Product Description

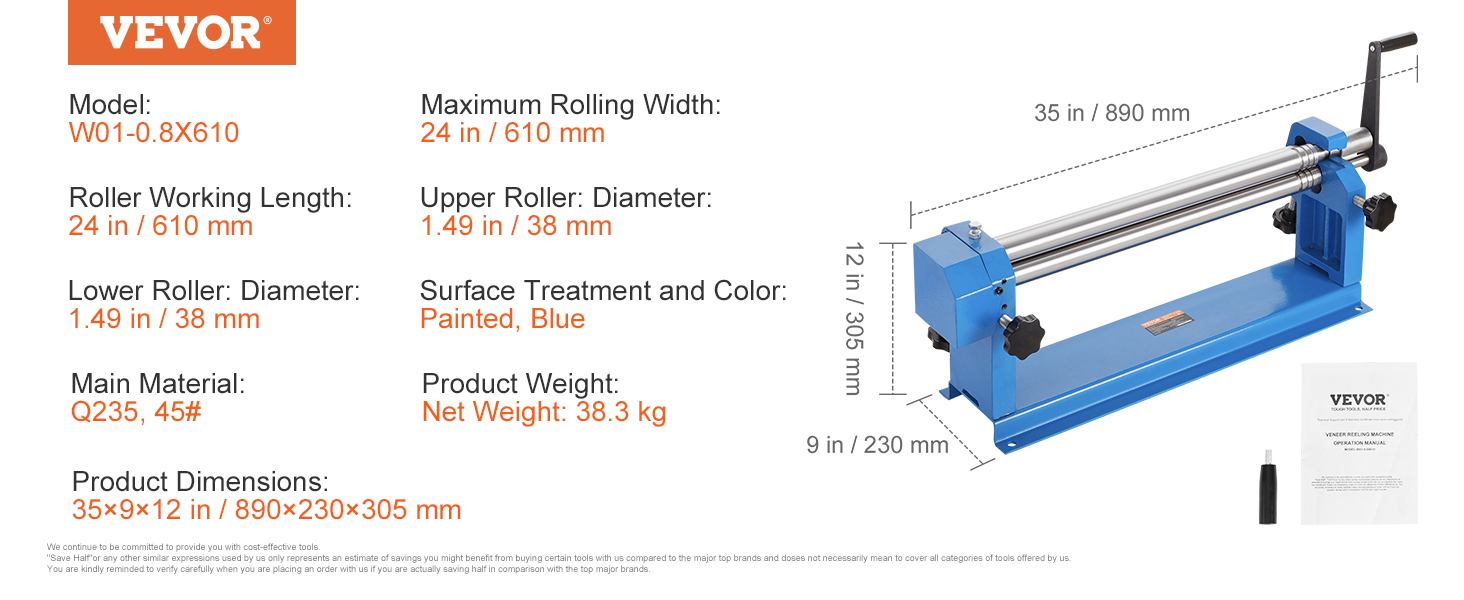

VEVOR 24-inch Slip Roll Machine

The new 24-inch slip roll machine has undergone comprehensive improvements in performance and quality, making it more efficient, easy to use, and secure for your rolling operations. It is the ideal choice for your sheet metal rolling tasks.

Our sheet metal slip roller reduces friction between the sheet metal and the rollers, enhancing machine stability during operation. Besides, it minimizes the occurrence of scratches on the sheet metal due to uneven roller surfaces, thereby improving the smoothness of the sheet metal's surface.

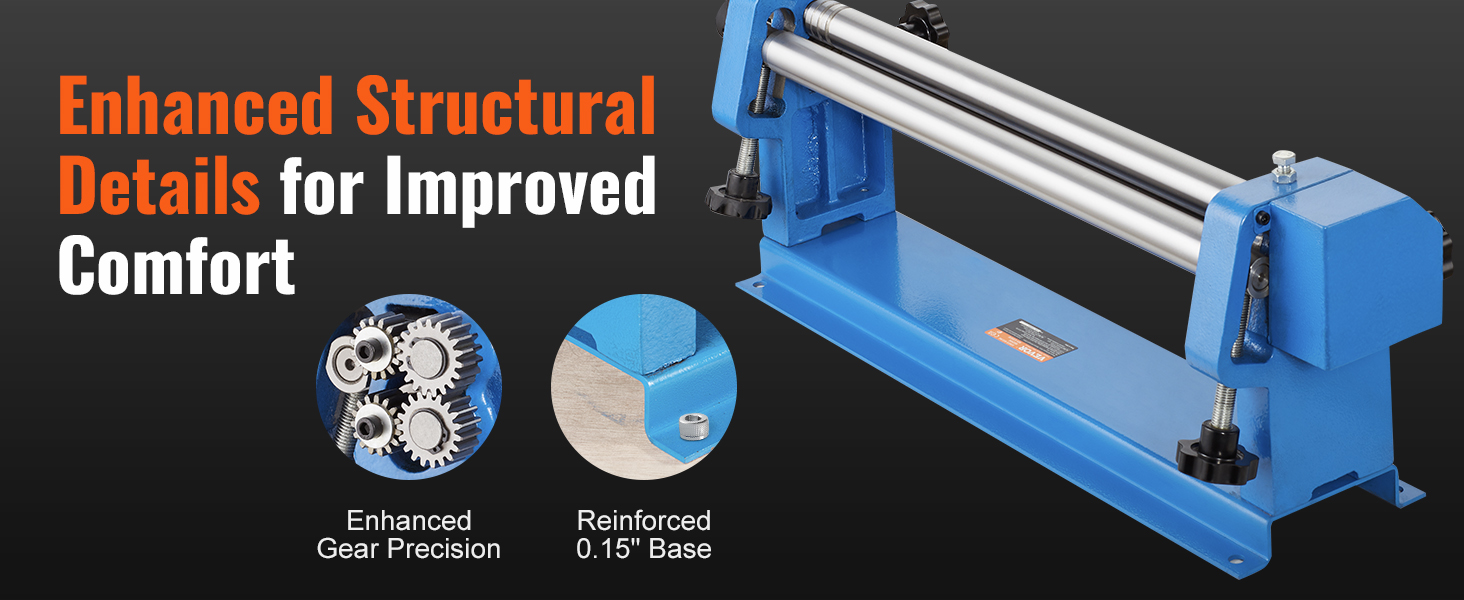

A 0.15-inch thick base enhances the overall stability of the machine during operation. Improved gear clearance control results in better gear engagement, smoother operation, and reduced roller axis rolling irregularities issues.

Our sheet metal slip roller's upper roller can be easily extended using the knob to retrieve processed workpieces conveniently.

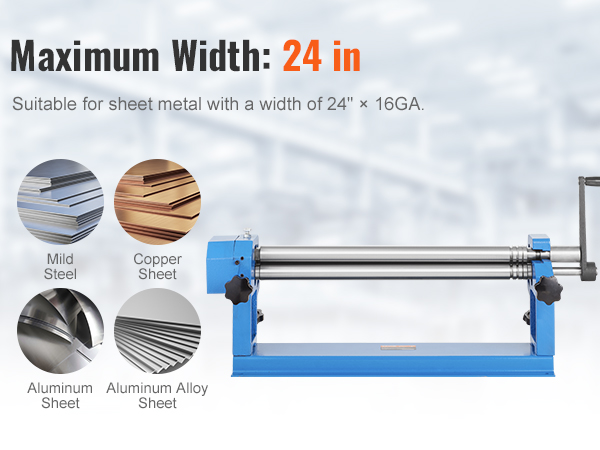

This metal slip roller can shape sheet metal into curved pieces, cones, and cylinders. It is suitable for various types of sheet materials, including low-carbon steel (Q235 and Q195), copper, aluminum, and aluminum alloys, among other mainstream sheet materials.

Features & Details

- Newly Upgraded Roller Surface: The roller is processed using state-of-the-art cylindrical grinding technology, which has several benefits. On the one hand, it reduces friction between the sheet metal and the roller, enhancing the machine's stability during operation. On the other hand, it minimizes surface irregularities on the roller, avoiding scratches on the sheet metal due to uneven roller surfaces, thereby improving the smoothness of the sheet metal surface.

- Thickened Base: The base has been reinforced to 0.15''/4 mm in thickness, significantly improving the machine's overall stability. The base ensures that the slip roll machine operates without wobbling or shaking during sheet rolling.

- Enhanced Gear Clearance Control: We have optimized the precision adjustment of gear clearances, resulting in better gear meshing, improved accuracy, smoother operation, and a substantial reduction in roller axis-related issues where the rollers don't roll smoothly.

- Detachable Rollers: The upper shaft of our sheet metal slip roller can be easily pulled out for convenient disassembly of processed workpieces. There are two rollers with three grooves each, which can be used for wire shaping.

- Built-in Stainless Steel Gear Guard: Our metal slip roller comes with a built-in stainless steel gear guard for a dual purpose. Firstly, it ensures security by avoiding accidental contact with the gears during operation, and secondly, it protects the gears from external exposure, thus extending the machine's lifespan.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR's products are sold in more than 200 countries and regions with 10 million plus members worldwide.

VEVOR 24-inch Slip Roll Machine

The new 24-inch slip roll machine has undergone comprehensive improvements in performance and quality, making it more efficient, easy to use, and secure for your rolling operations. It is the ideal choice for your sheet metal rolling tasks.

Our sheet metal slip roller reduces friction between the sheet metal and the rollers, enhancing machine stability during operation. Besides, it minimizes the occurrence of scratches on the sheet metal due to uneven roller surfaces, thereby improving the smoothness of the sheet metal's surface.

A 0.15-inch thick base enhances the overall stability of the machine during operation. Improved gear clearance control results in better gear engagement, smoother operation, and reduced roller axis rolling irregularities issues.

Our sheet metal slip roller's upper roller can be easily extended using the knob to retrieve processed workpieces conveniently.

This metal slip roller can shape sheet metal into curved pieces, cones, and cylinders. It is suitable for various types of sheet materials, including low-carbon steel (Q235 and Q195), copper, aluminum, and aluminum alloys, among other mainstream sheet materials.

Features & Details

- Newly Upgraded Roller Surface: The roller is processed using state-of-the-art cylindrical grinding technology, which has several benefits. On the one hand, it reduces friction between the sheet metal and the roller, enhancing the machine's stability during operation. On the other hand, it minimizes surface irregularities on the roller, avoiding scratches on the sheet metal due to uneven roller surfaces, thereby improving the smoothness of the sheet metal surface.

- Thickened Base: The base has been reinforced to 0.15''/4 mm in thickness, significantly improving the machine's overall stability. The base ensures that the slip roll machine operates without wobbling or shaking during sheet rolling.

- Enhanced Gear Clearance Control: We have optimized the precision adjustment of gear clearances, resulting in better gear meshing, improved accuracy, smoother operation, and a substantial reduction in roller axis-related issues where the rollers don't roll smoothly.

- Detachable Rollers: The upper shaft of our sheet metal slip roller can be easily pulled out for convenient disassembly of processed workpieces. There are two rollers with three grooves each, which can be used for wire shaping.

- Built-in Stainless Steel Gear Guard: Our metal slip roller comes with a built-in stainless steel gear guard for a dual purpose. Firstly, it ensures security by avoiding accidental contact with the gears during operation, and secondly, it protects the gears from external exposure, thus extending the machine's lifespan.