PRODUCT PARAMETERS

Product name: Power off four piston brake

Color: black, silvery,golden

Process: CNC, forging

Weight: 300g

Oil pipe length: 2300mm

Material: high-strength aluminum alloy

Braking direction: left front right rear (oil pipe can be disassembled, right front left rear can be reassembled)

Rotor: Caliper compatible with 140/160/180/203mm brake discs.

The original caliper is suitable for 160mm brake discs.

If you want to use 180mm or 203mm brake discs,

You need to use a brake adapter

(Original brake does not include 180mm and 203mm adapters

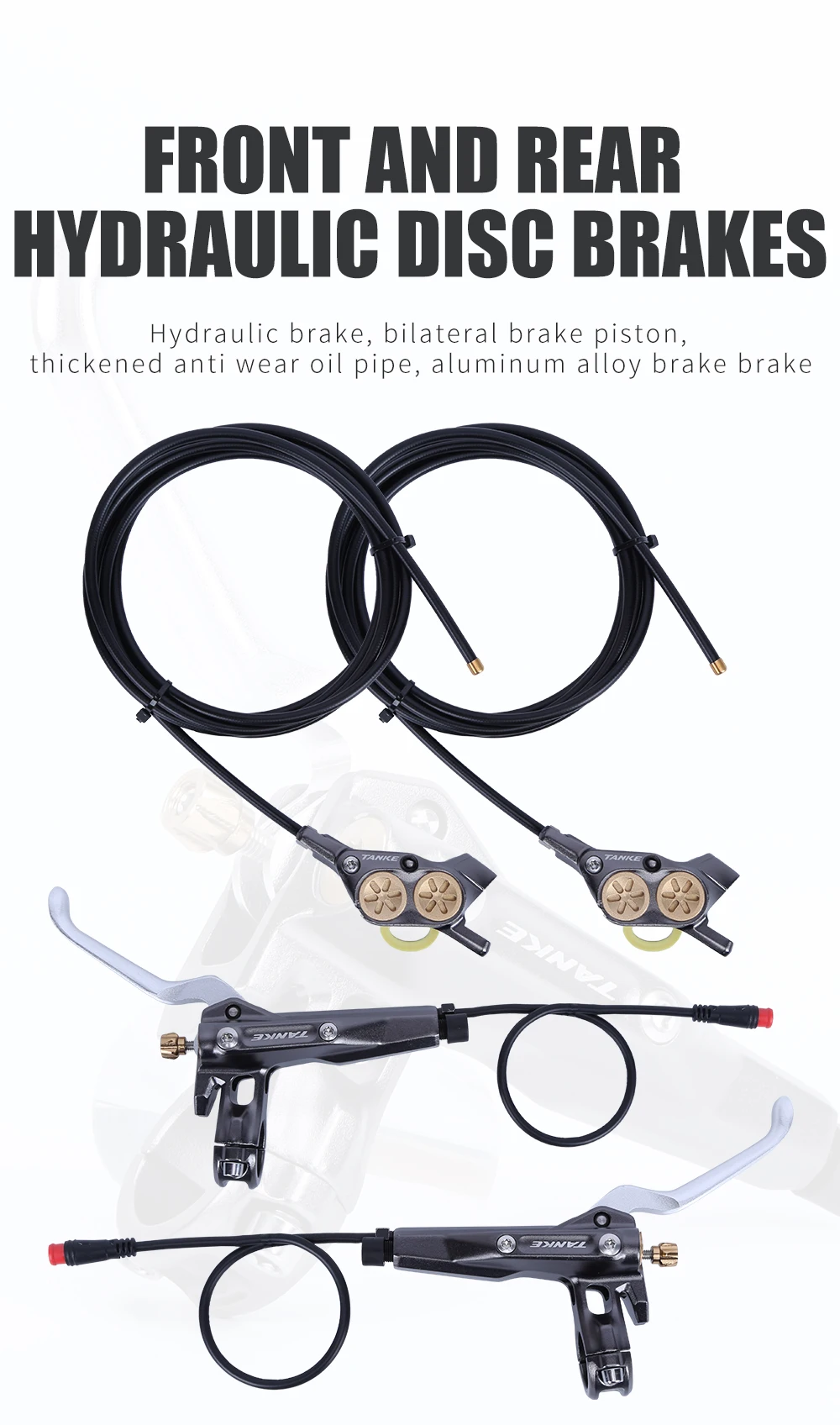

FOUR PISTON DUAL BRre makes the brake pads more balanced FRONT AND REAR HYDRAULIC DISC BRAKES

FRONT AND REAR HYDRAULIC DISC BRAKES

Hydraulic brake, bilateral brake piston, thickened anti wear oil pipe, aluminum alloy brake brake

HIGH QUALITY ALUMINUN ALLOY HANDLE

HIGH QUALITY ALUMINUN ALLOY HANDLE

Strong sealing, reducing maintenance frequency, The appearance is simple and ergonomic,

Adopting lightweight design with dual finger brake handle,Internal Hexagram screw BRAKE HANDLE WIRING PORT

BRAKE HANDLE WIRING PORT UPGRADE THE FOUR PISTON CALIPER STRUCTURE

UPGRADE THE FOUR PISTON CALIPER STRUCTURE

General brake single piston principle

Unilateral drive friction plate

The elastic deformation of the disc causes friction to the other side, and as the usage time increases, the friction between the left and right sides of the disc is uneven, resulting in limited braking force.

Working principle of dual piston drive

Double sided simultaneous drive friction plate

The disc is always kept in the center without tilting, with synchronous friction on both sides, ensuring smooth braking and doubling the braking force. It is durable and its braking performance is not easily degraded. HYDRAULIC DISC BRAKE OIL PIPE

HYDRAULIC DISC BRAKE OIL PIPE

The brake oil pipe is made of high-density and low elastic materials

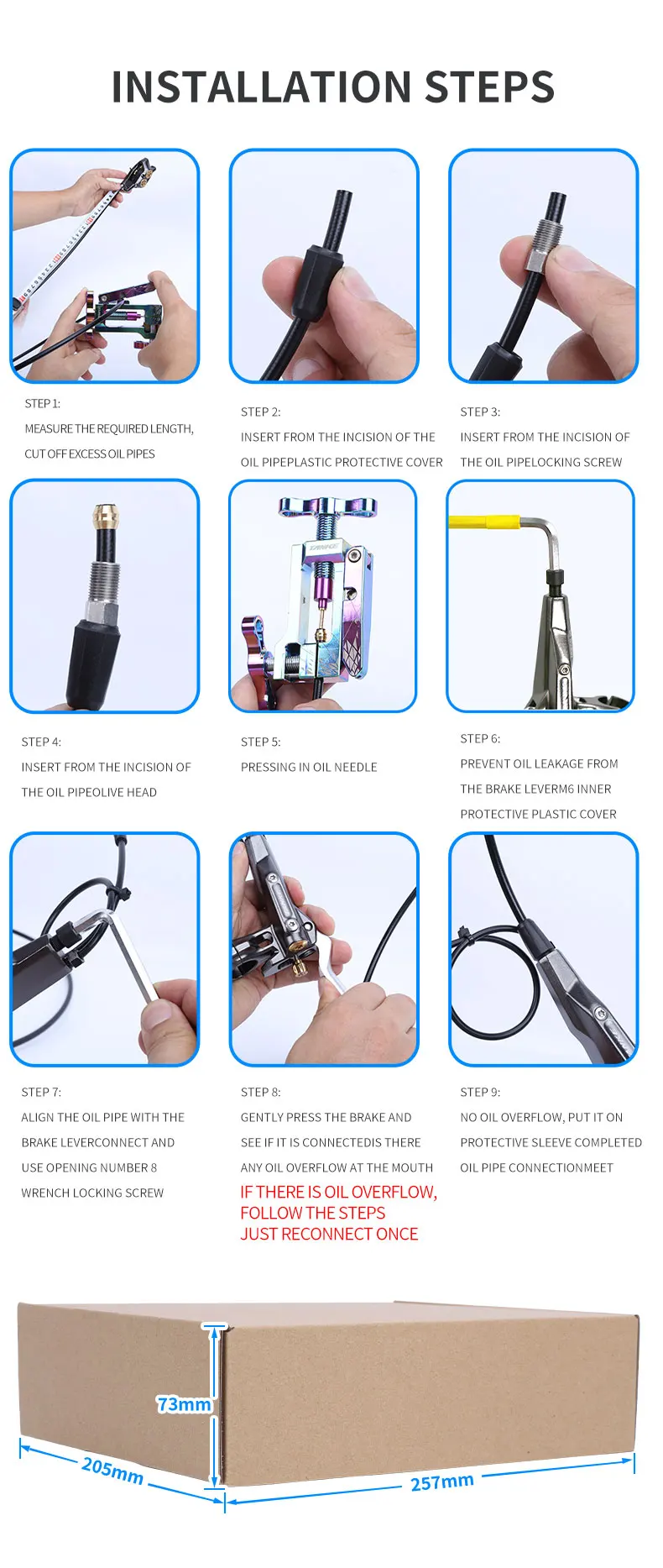

INSTALLATION STEPS

INSTALLATION STEPS

Step 1:

Measure the required length and cut off excess oil pipes

Step 2: Insert a plastic protective cover from the oil pipe incision

Step 3: Insert the locking screw from the oil pipe incision

Step 4: Insert the olive head from the oil pipe incision

Step 5:

Pressing in oil needle

Step 6: Use an M6 Hex key to remove the plastic cover for oil leakage protection of the brake handle

Step 7:

Connect the oil pipe to the brake handle and tighten the screws with an 8 # open-ended wrench

Step 8: Gently press the brake and check if there is any oil overflow at the interface to complete the oil pipe

Step 9:

There is no oil overflow, put on a protective sleeve connection

If there is an oil spill, follow the steps to reconnect it once again