Product Description

VEVOR Floor Cutter-The Secret of Effortless Cutting

Utilizing the lever principle by adjusting the bearing position to find the optimal load-bearing point, combined with the hardness of aluminum alloy, and an extended handle to instantly amplify force, making it easy to cut through objects.

Our genuine mold steel blades are harder, more durable, and resistant compared to regular steel blades. Be cautious not to cut unauthorized materials like solid wood flooring, as it may damage the blade permanently.

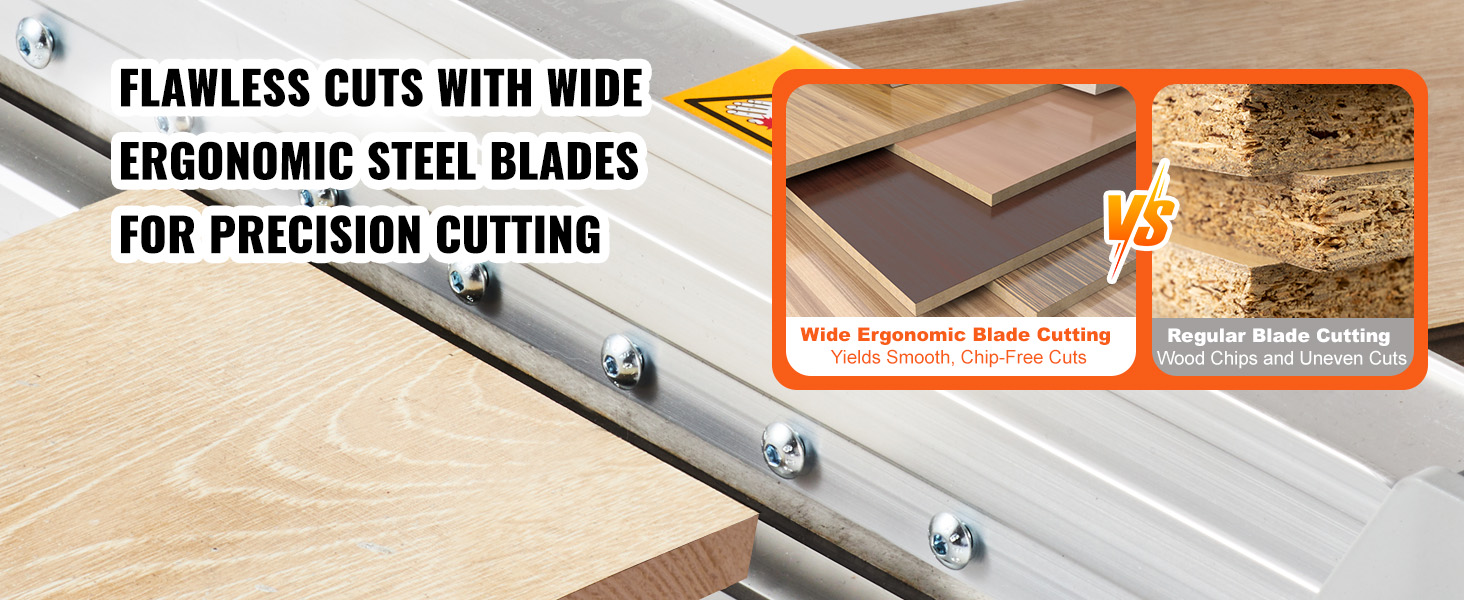

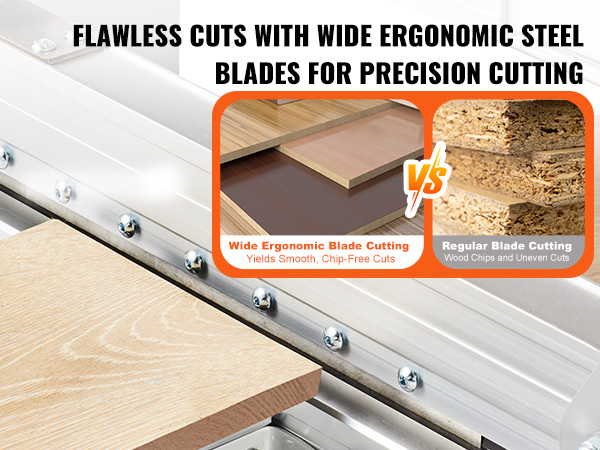

We've innovatively designed a wide blade for improved sharpness, reduced cutting resistance, and smoother, faster, and more even cuts while maintaining blade sharpness.

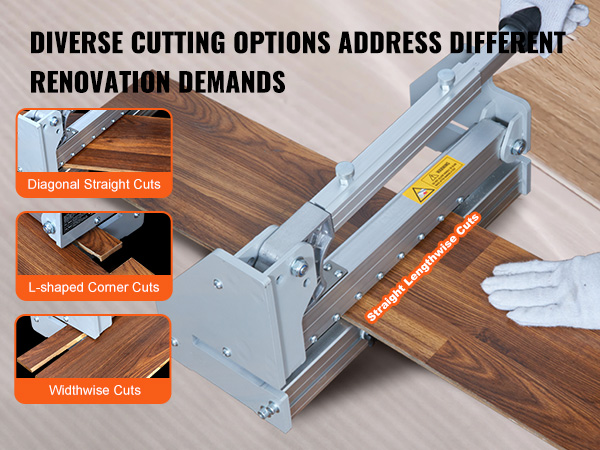

Construction sites often require special cutting modes for different scenarios, such as L-shaped corner cuts for pillars and door edges, and width cuts for walls. Multiple modes meet various needs, improving work efficiency and cutting quality.

We provide a sharpening stone as a thoughtful addition. To use it, maintain an angle of about 20° between the blade and the stone, and slide the blade back and forth with even pressure and speed. This process quickly restores blade sharpness and extends its lifespan.

Features & Details

- Effortless Cutting: Utilizing the lever principle, by adjusting the bearing position to find the golden load-bearing point, combined with the hardness of aluminum alloy, and an extended handle to amplify the force instantly, easily cut through objects.

- 0.47in/12mm Cutting Thickness: Using genuine 0.47in/12mm mold steel blades, they are tougher and more durable than ordinary steel. Can easily cut various types of popular flooring materials, including laminate, vinyl plank (LVP, SPC, WPC, VCT, vinyl), and carpet tiles.

- Multiple Cutting Modes: In addition to regular straight cuts, various cutting modes are needed on construction sites for special scenarios, such as L-shaped corner cuts for pillars and door edges, and width cuts for walls. Multiple modes meet different requirements, improving work efficiency and cutting quality.

- Smooth and Crack-Free Cuts: Innovative wide blade blades reduce the contact surface between the blade and the object, reducing cutting resistance, resulting in faster cutting speeds, smoother and flatter cuts, while maintaining blade sharpness.

- Free Sharpening Stone Included: The blade is sharpened at an angle of about 20° by sliding it back and forth on the sharpening stone while maintaining even pressure and speed. This process quickly restores blade sharpness and extends its lifespan.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR's products are sold in more than 200 countries and regions with 10 million plus members worldwide.

VEVOR Floor Cutter-The Secret of Effortless Cutting

Utilizing the lever principle by adjusting the bearing position to find the optimal load-bearing point, combined with the hardness of aluminum alloy, and an extended handle to instantly amplify force, making it easy to cut through objects.

Our genuine mold steel blades are harder, more durable, and resistant compared to regular steel blades. Be cautious not to cut unauthorized materials like solid wood flooring, as it may damage the blade permanently.

We've innovatively designed a wide blade for improved sharpness, reduced cutting resistance, and smoother, faster, and more even cuts while maintaining blade sharpness.

Construction sites often require special cutting modes for different scenarios, such as L-shaped corner cuts for pillars and door edges, and width cuts for walls. Multiple modes meet various needs, improving work efficiency and cutting quality.

We provide a sharpening stone as a thoughtful addition. To use it, maintain an angle of about 20° between the blade and the stone, and slide the blade back and forth with even pressure and speed. This process quickly restores blade sharpness and extends its lifespan.

Features & Details

- Effortless Cutting: Utilizing the lever principle, by adjusting the bearing position to find the golden load-bearing point, combined with the hardness of aluminum alloy, and an extended handle to amplify the force instantly, easily cut through objects.

- 0.47in/12mm Cutting Thickness: Using genuine 0.47in/12mm mold steel blades, they are tougher and more durable than ordinary steel. Can easily cut various types of popular flooring materials, including laminate, vinyl plank (LVP, SPC, WPC, VCT, vinyl), and carpet tiles.

- Multiple Cutting Modes: In addition to regular straight cuts, various cutting modes are needed on construction sites for special scenarios, such as L-shaped corner cuts for pillars and door edges, and width cuts for walls. Multiple modes meet different requirements, improving work efficiency and cutting quality.

- Smooth and Crack-Free Cuts: Innovative wide blade blades reduce the contact surface between the blade and the object, reducing cutting resistance, resulting in faster cutting speeds, smoother and flatter cuts, while maintaining blade sharpness.

- Free Sharpening Stone Included: The blade is sharpened at an angle of about 20° by sliding it back and forth on the sharpening stone while maintaining even pressure and speed. This process quickly restores blade sharpness and extends its lifespan.