High-efficiency Five-axis 3000W Automatic Fiber Laser Welder Spot Weld Fast Welding Speed

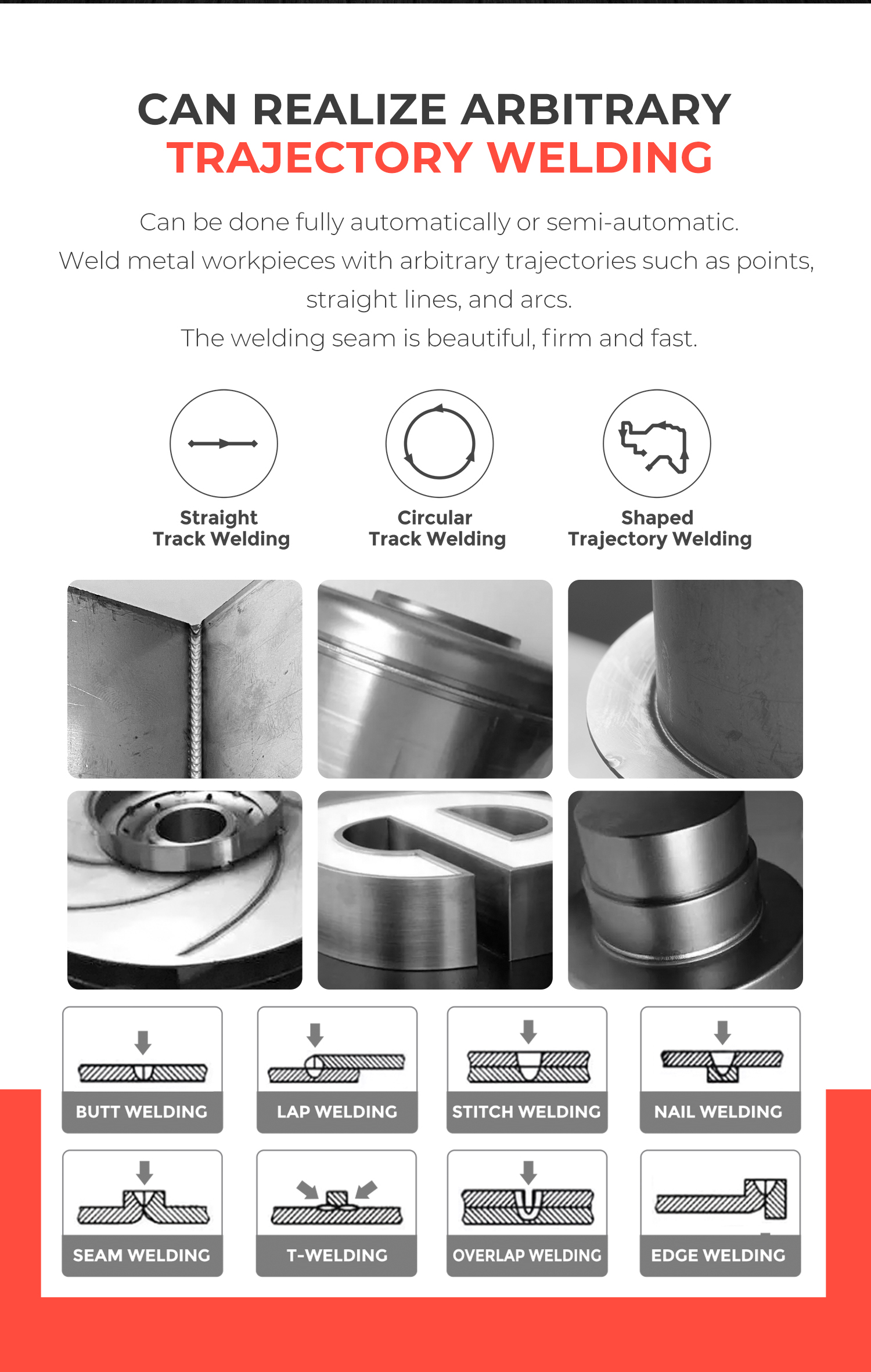

The welding process can be done fully automatically or semi-automatic with this automatic welding machine. It can achieve straight-track welding, circular-track welding, and shaped trajectory welding. The automatic laser welding machine can be used to weld metal workpieces with arbitrary trajectories such as points, straight lines, and arcs. It can weld stainless steel, die steel, carbon steel, nickel, zinc, aluminum, etc., especially in thin plate welding has obvious advantages. The laser welding machine is widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automobile manufacturing, and other industries. The welding seam is beautiful, firm, and fast.

The price here is with standard configuration: MAX laser source, Hanli water chiller. If an upgrade is needed, please contact us for customization.

Specifics:

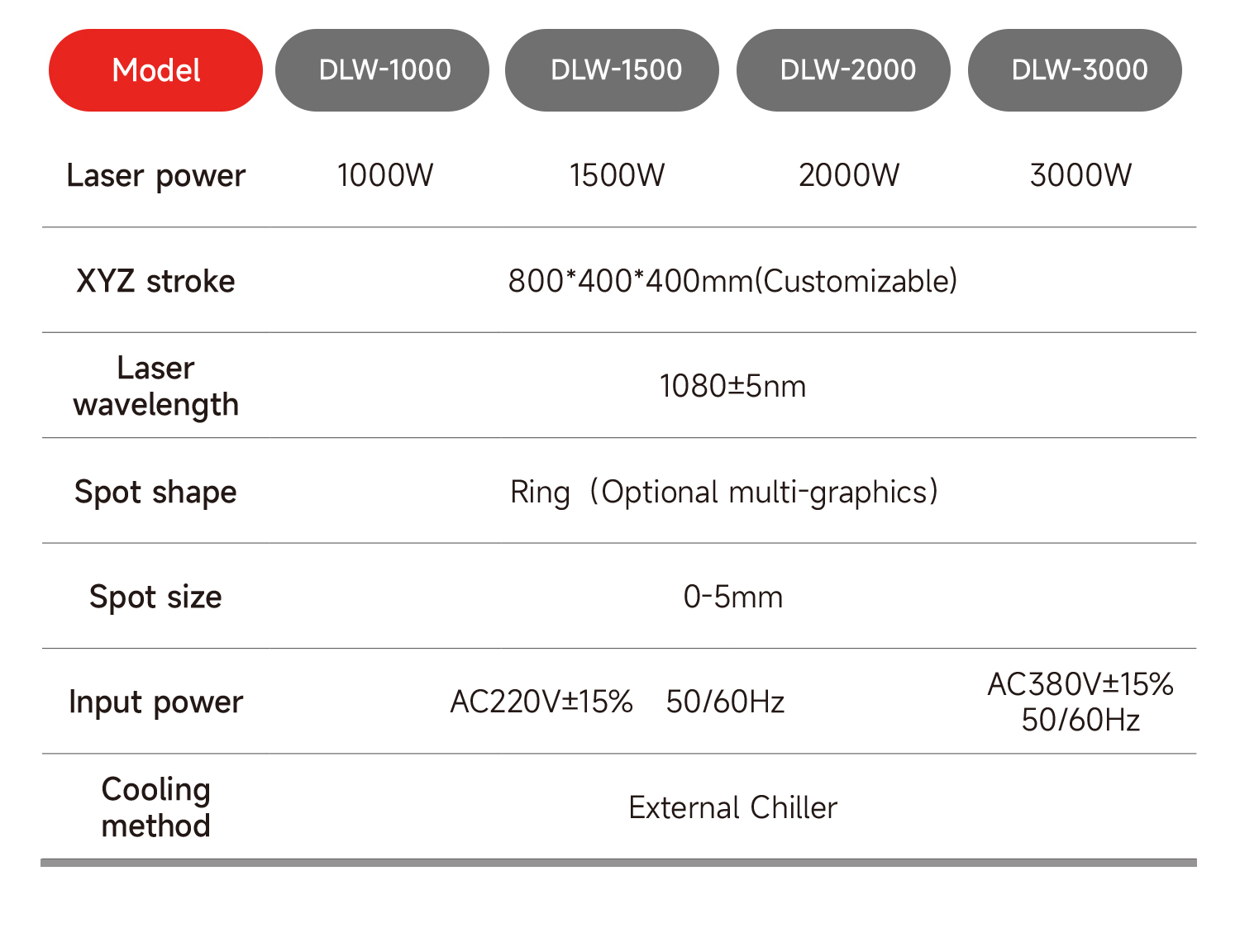

- Model: DLW-3000

- Name: 3000W Automatic Laser Welder

- Laser Power: 3000watt

- Laser Source: Fiber Laser MAX, 1080nm

- XYZ stroke: 800*400*400mm(customizable)

- Spot shape: Ring (Optional multi-graphics)

- Cooling Method: External chiller

- Spot size: 0-5mm

- Input power: AC380V±15% 50/60Hz

- Machine dimension: 1500*1300*1750mm

Advantages:

1. Beautiful weld seam

Less polishing and grinding, better work efficiency

2. Maintenance free

Modular design for the whole machine, stable performance

3. Easy to operate

Simple operation, low cost, and low requirements for workers

4. Wide application

Wide range of applications, high precision, fast

5. High power

The high aspect ratio of the weld seam, small heat-affected area, small deformation, fast welding speed

6. Long service life

Newly laser technology, the service life can reach more than tens of thousands of hours

Features:

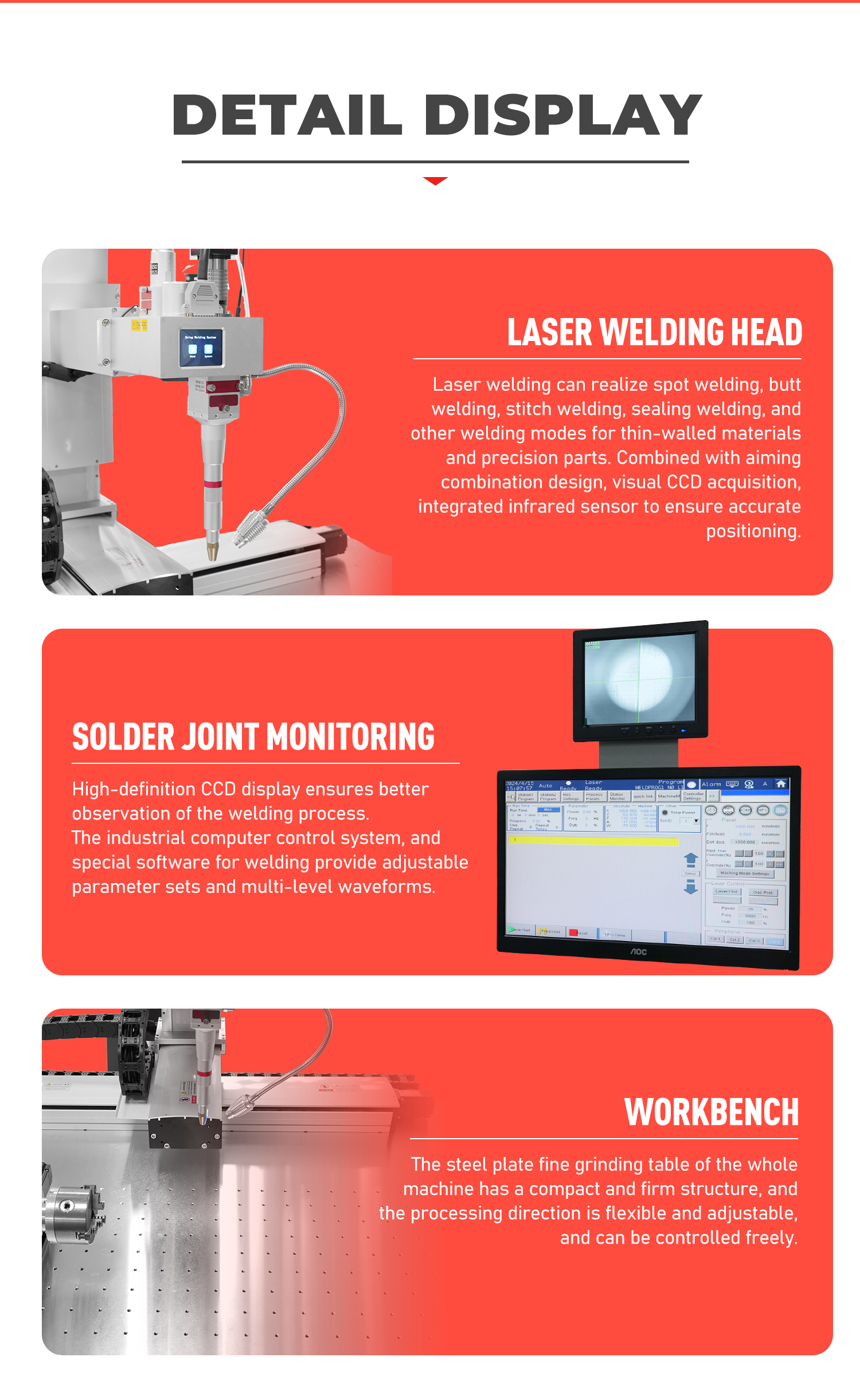

1. LASER WELDING HEAD

Laser welding can realize spot welding, butt welding, stitch welding, sealing welding, and other welding modes for thin-walled materials and precision parts. Combined with aiming combination design, visual CCD acquisition, and integrated infrared sensor to ensure accurate positioning.

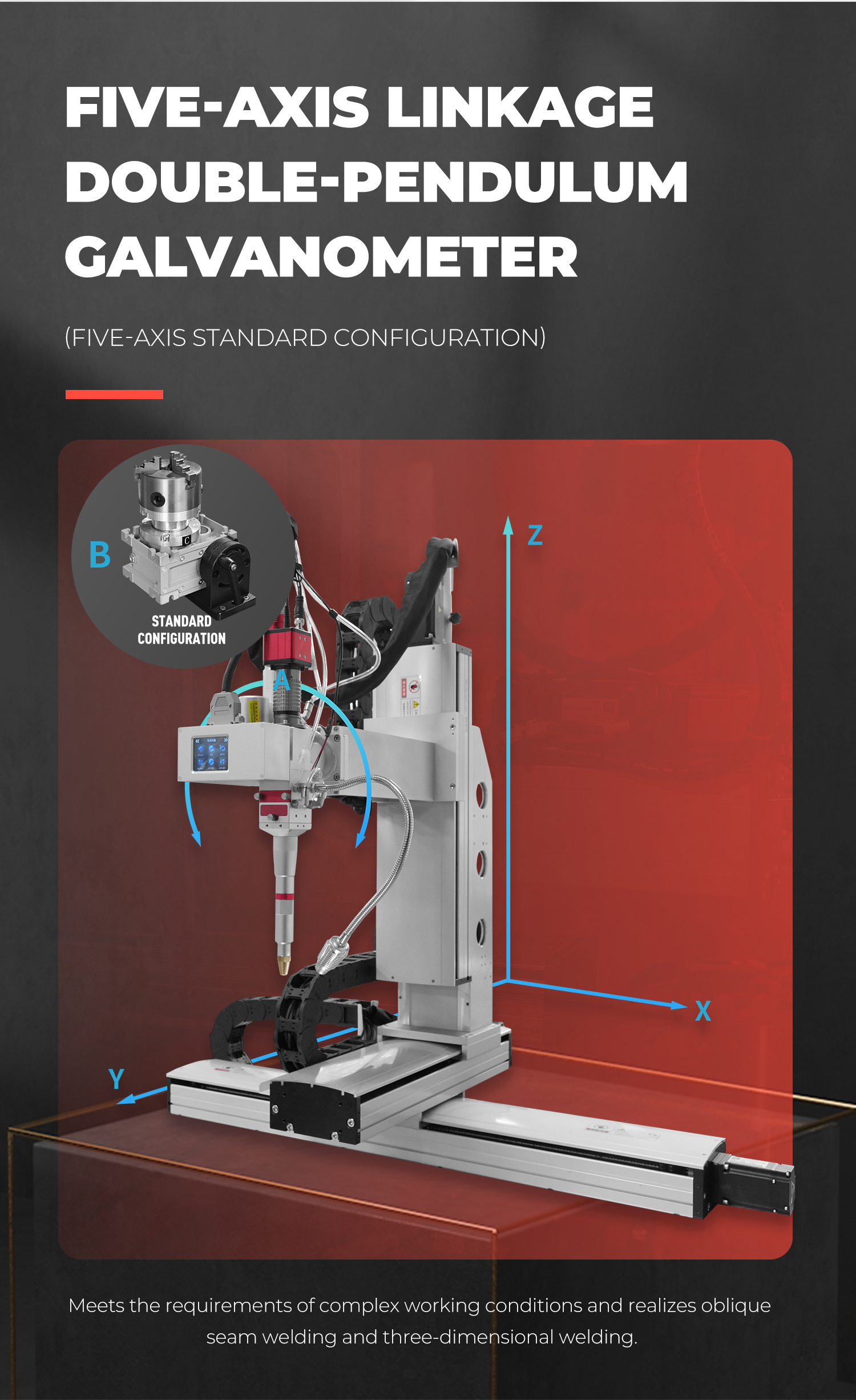

2. MULTI-AXIS SERVO WELDING TABLE

High positioning accuracy, sensitive response, shockproof design, no need to move the product manually, automatic movement for welding

3. SOLDER JOINT MONITORING

High-definition CCD display ensures better observation of the welding process. The industrial computer control system and special software for welding provide adjustable parameter sets and multi-level waveforms.

4. WORKBENCH

The steel plate fine grinding table of the whole machine has a compact and firm structure, and the processing direction is flexible and adjustable and can be controlled freely.

Payment and Shipping:

The machine will be shipped out by sea about 15 days after placing the order.

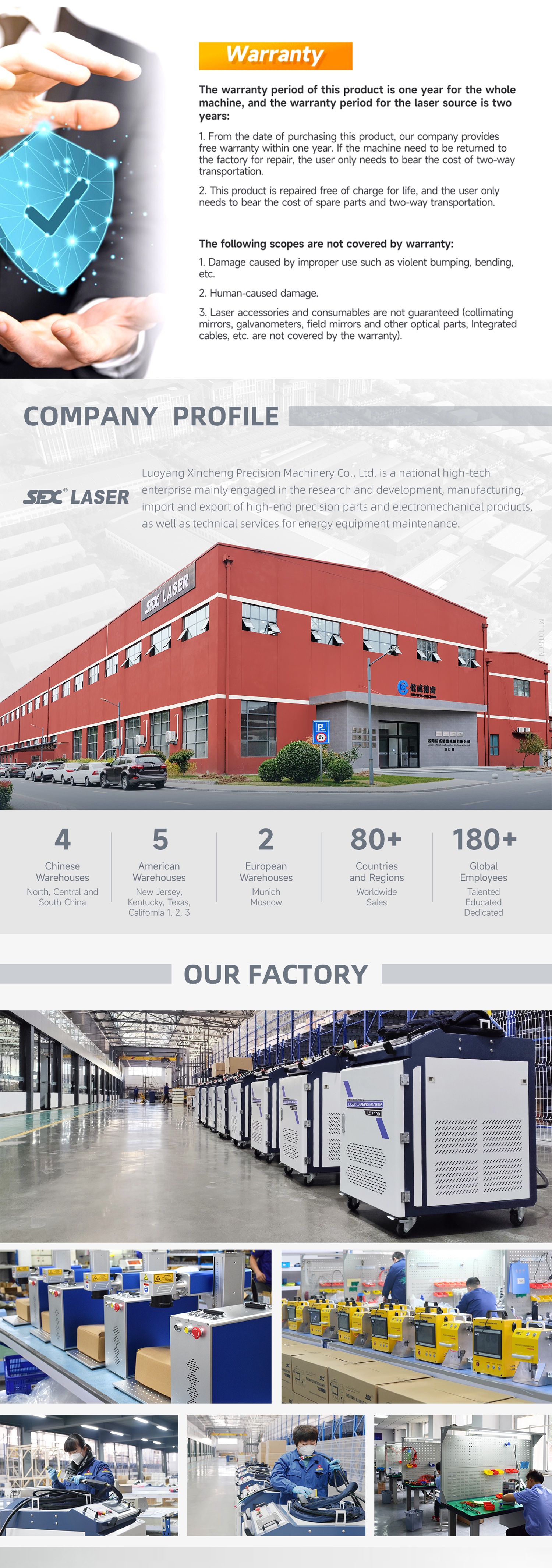

Warranty and lifetime technical support are provided, with no worry about after-sales.