Products Description

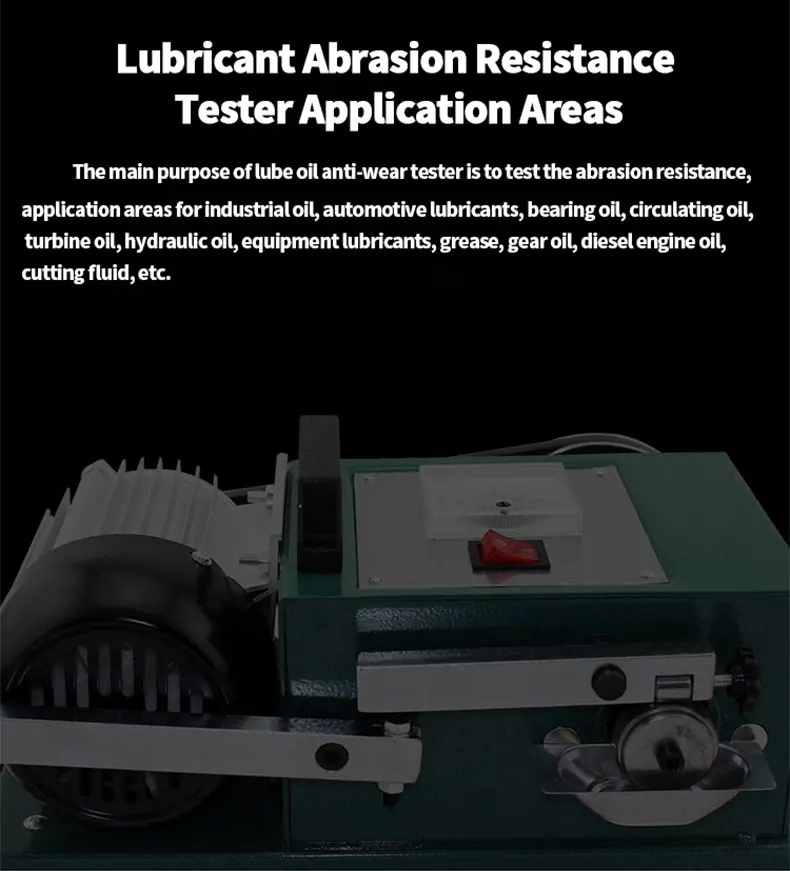

The new lubricating oil anti-wear testing machine, referred to as the anti-wear testing machine, is based on the test principle of the American ring block testing machine (Timken testing machine), and the main functions are simplified. Intuitively reflect the anti-wear and anti-friction performance of lubricating oil. The main working part is composed of a grinding ring that rotates with the main shaft and a fixed grinding column pressed on the grinding ring. During the test, under different pressure conditions, the friction between the grinding ring and the grinding column is generated. Sliding friction, so it is also called a simplified version of the ring block testing machine (Timken testing machine) The anti-wear testing machine can test the strength of the lubricating oil film and the strength (quantitative reflection) of the anti-wear protective layer formed by the anti-wear agent on the metal friction contact surface through the force system composed of weights and levers, and its extreme pressure (OK value) has a certain approximate correspondence with the four-ball machine (Pa value); at the same time, through the motor load ammeter on the instrument panel, the friction change of the friction surface can be reflected (qualitative reflection).

Because the anti-wear testing machine can quickly and concisely reflect the anti-wear and anti-friction properties of lubricating oil, it is often used in the production, research and development and promotion of lubricating oil or anti-wear agent with better anti-wear performance.

Product Paramenters

|

Lubricant Testing Machine Parameters

|

|

|

|

Name

|

LubricantAbrasion Resistance Tester

|

|

|

Standard

|

CE ASTM CQ AFM

|

|

|

Power

|

230W / 280W

|

|

|

Processing, accuracy

|

0.01 mm

|

|

|

Display method

|

Pointer/Digital display

|

|

|

L ever ratio

|

13.745

|

|

|

Machine weight

|

23kg

|

|

|

Ball size

|

14*14mm

|

|

|

Voltage

|

220V / 110V

|

|

|

Machine Size

|

340*200*1 70mm

|

|

|

lron box packing size

|

400*250*210mm

|

|

|

Air box packing size

|

480*290*270mm

|

|

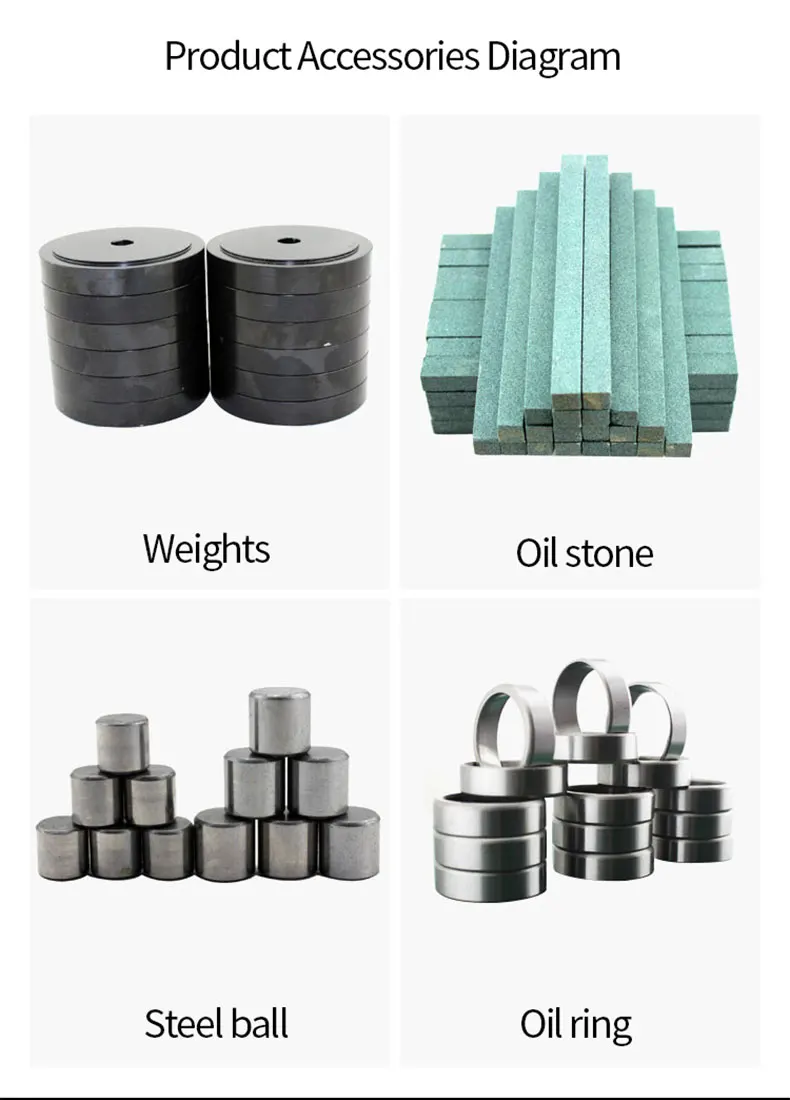

Product Packing List