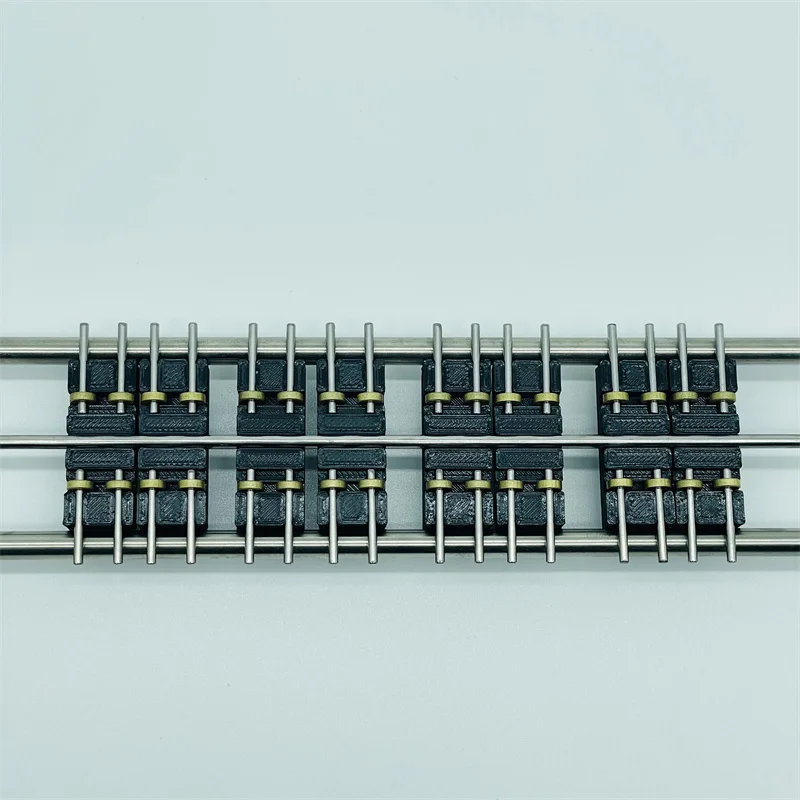

For HO, the total length is 50cm, eight pairs of wheels, and millions of ordinary connecting lines for easy connection. Firmware 3D printing, 304 solid stainless steel shaft, copper alloy oil bearing.

The improvement uses the model-specific gold-plated banana plug and stainless steel shaft for precision welding, striving to reduce the current loss, making the front drive work more stable and the rotation more delicate.

High-precision printing of 3d printed parts ensures installation accuracy and module strength.

The bearing is a powder metallurgy oil-impregnated copper bearing produced by a bearing factory supplied by a Japanese company. The copper base of the bearing is softer than the wheel material and protects the front metal wheel from wear.The positioning steel pin is made of bearing steel, which is harder and more wear-resistant.