100g Soldering Paste Flux Silver Brass Brazing For Welding Copper Alumi.go

[VIDEO1]

Preview:

Thank you for your purchase

Problems?

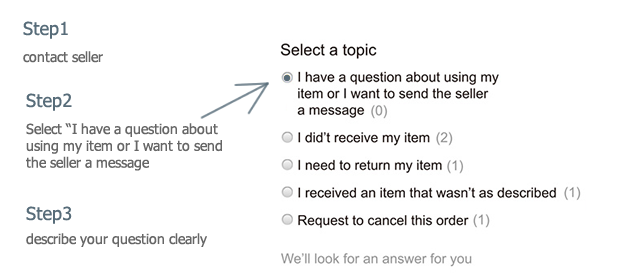

You can follow below process to chontact us. There is a time zone difference,but we will do our best to quickly response to your questions:

Shipping

● We will arrange shipping for you within 2-5 days after payment cleared except the holidays.

● We always send the item to the address you give us on PAYPAL to ensure the security of the item. If you have changed your address, or want us to ship to another address, please change to the new address when you pay us with PAYPAL, otherwise we will not be responsible if the package is lost.

Payments

We accepts Paypal only If you have any questions about the payment,please contact us through eBay message.

Import Duties

In case some duty is due Upon delivery, it is your responsibility to meet that expense and this may cause delays to delivery schedule and you may have to pickup goods at the customs office.

Terms & Conditions

By bidding on this item,the Buyer agrees to all of the terms and conditions as outlined in this listing .please ensure to read and agree to All eBay terms and Conditions before bidding.

All pictures are for illustration purpose only and Colours may vary slightly.

Our store obeys all eBay Rules and Policies.

Returns Policy

To Return an item you must contact us and take photos of your item to clearly show any damage or unusual aspects of it.

Approved returns will be subject to inspection on arrival. Items must be returned in original condition with all original packaging.

All shipping and handing charges are non-refundable

Return delivery costs are the responsibility of the buyer. We will cover the cost if sending replacement/repaired items.

Within 7 days after receiving your products, we offers a no-hassle 7 day exchange/replace only if your items are found to be defective by manufacturer.