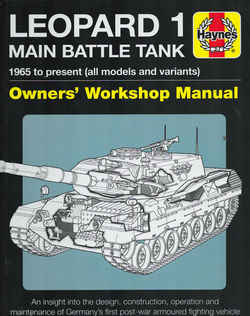

HAYNES LEOPARD I GERMAN MBT GEPARD

FLAKPANZER BIBER BRIDGELAYER BUFFELL ARV COMBAT ENGINEER

HARDBOUND

BOOK in ENGLISH by MICHAEL K. CECIL and MICHAEL SHACKLETON

OWNER’S

WORKSHOP MANUAL

***BRAND

NEW CONDITION***

HEAVILY

ILLUSTRATED WITH HUNDRED OF PHOTOGRAPHS (BOTH COLOR & BW) AS WELL AS

DIAGRAMS, DETAIL ILLUSTRATIONS AND DATA TABLES

LEOPARD

1A1, LEOPARD 1A2, LEOPARD 1A3, LEOPARD 1A4, LEOPARD 1A5

1961

PROTOTYPE

PROTOTYPE

A2

PRODUCTION

– KRAUSS-MAFFEI A.G.

TAUCHSCHACHT

SWIMMING AMPHIBIOUS TANK

MTU

MB 838 ENGINE

FOREIGN

SERVICE (BELGIUM, NORWAY, NETHERLANDS, ITALY, DENMARK, AUSTRALIA, CANADA,

TURKEY, GREECE)

120MM

SMOOTHBORE CANNON

NIGHT-FIGHTING

MODIFICATIONS

KRAUSE-MAFFEI

PIONIERPANZER COMBAT ENGINEER TANK MODIFICATIONS

FAHRSCHULPANZER

DRIVER TRAINING TANK

BUFFEL

BERGEPANZER ARMOURED RECOVERY VEHICLE

FLAKPANZER

GEPARD

BIBER

BRUCKENLEGEPANZER BRIDGELAYER

KAMPFPANZER

70

KAMPFPANZER

LEOPARD 2

PROTOTYPE

PRODUCTION

-------------------------------

Additional Information from

Internet Encyclopedia

The Kampfpanzer Leopard 1 (also

styled Leopard I, before the Leopard 2 simply known as the Kampfpanzer Leopard)

is a main battle tank designed by Porsche and manufactured by Krauss-Maffei in

West Germany, first entering service in 1965. Developed in an era when HEAT warheads

were thought to make conventional heavy armour of limited value, the Leopard

design focused on effective firepower and mobility instead of heavy protection.

It featured moderate armour, only effective against low caliber autocannons and

heavy machine guns, giving it a high power-to-weight ratio. This, coupled with

a modern suspension and drivetrain, gave the Leopard superior mobility and

cross-country performance compared to most other main battle tanks of the era,

only being rivaled by the French AMX-30 and Swedish Strv 103. The main armament

of the Leopard consisted of a German license-built version of the British Royal

Ordnance L7 105 mm rifled gun, one of the most effective and widespread tank

guns of the era.

The design started as a

collaborative project during the 1950s between West Germany and France, and

later joined by Italy,[1] but the partnership ended shortly after and the final

design was ordered by the Bundeswehr, with full-scale production starting in

1965. In total, 6485 Leopard tanks have been built, of which 4744 were battle

tanks and 1741 were utility and anti-aircraft variants, not including 80

prototypes and pre-series vehicles.

The Leopard quickly became a

standard of many European militaries, and eventually served as the main battle

tank in over a dozen countries worldwide, with West Germany, Italy and the

Netherlands being the largest operators until their retirement. Since 1990, the

Leopard 1 has gradually been relegated to secondary roles in most armies. In

the German Army, the Leopard 1 was completely phased out in 2003 by the Leopard

2, while Leopard 1-based vehicles are still widely used in utility roles.

The Leopard 2 has replaced the

Leopard 1 in service with many other nations, with derived vehicles using the

Leopard 1 hull still seeing service. Currently, the largest operators are

Greece, with 520 vehicles, Turkey, with 397 vehicles, Brazil with 378 vehicles

and Chile with 202 vehicles. Most of these vehicles have been upgraded with

various improvements to armour, firepower and sensors to maintain their ability

to engage modern threats.

Development

The Leopard project started in

November 1956 in order to develop a modern tank, the Standard-Panzer, to

replace the Bundeswehr's American-built M47 and M48 Patton tanks, which, though

just delivered to West Germany's recently reconstituted army, were rapidly

becoming outdated. On 25 July 1957, the detailed specifications were released.

The new design needed to weigh no more than 30 tonnes, have a power-to-weight

ratio of 30 horsepower per tonne, be able to withstand hits by 20 mm rapid-fire

guns on every side as well as to operate in a battlefield contaminated with

chemical weapons or radioactive fallout, the then-standard baseline for combat

with the Warsaw Pact.

The main armament had to consist

of a 105 mm caliber weapon (the new British L7A3 105 mm gun was selected),[3]

carrying at least as many rounds as current US tank designs. Mobility had

priority, while firepower came second. Armour was seen as less essential, as it

was believed that no real protection against hollow charge weapons was possible

anyway. At the time it was suspected that future conflicts would involve

nuclear weapons, which no tank at the time could directly protect from.

France was very interested in

the design as its own AMX 50 project had just failed. In June 1957, West

Germany and the French Fourth Republic signed an agreement to develop a common

tank, designated in German Europa-Panzer. Three German (Arbeitsgruppe A, B and

C) and one French design team were included in a competition, with each team

producing two prototypes. In September 1958, Italy joined the development

program. Several prototypes were entered for testing in 1960. Among the

prototypes were Porsche's Model 734 from team A, sporting a cast turret, and

that of team B (Rheinmetall), whose cast turret was somewhat higher. Team C

from Borgward, designing a very futuristic tank, failed to have a prototype

ready in time.

Even before these first

prototypes were finished, it had (in 1959) been decided that a second phase

with improved designs would be started: Team A had to build 26 phase II

prototypes for testing, team B six. Only two tanks of the required six were

constructed by team B.

The Porsche Prototype II was

eventually selected as the winner of the contest in 1963. This did not come as

a surprise: it had already been decided in 1961 to build a pre-series of 50

vehicles based on this design. Production of these was started that very year.

This "0-series" was modified with a new cast turret and several hull

changes to raise the rear deck to provide more room in the engine compartment

and move some of the radiators to the upper sides of the hull. Before mass

production of the standard version started, it was decided to add an optical

range-finding system for better long-range gunnery, which required the turret

to be somewhat taller, and added "bumps" on either side of the turret

to mount the optics for triangulation. Germany dropped France from the joint

program after France repeatedly missed deadlines for its contribution to the

program.

In February 1963 Defence

Minister Kai-Uwe von Hassel announced he would soon ask the defence committee

in Parliament to approve production of the tank. At this time the tank weighed

40 tons and cost $250,000 each.[4] In July the Defence Ministry ordered 1,500

tanks with production to take place between 1965 and 1970. Germany also

announced its agreement to develop a successor with the United States. Called

the MBT-70, the program failed to materialize a tenable design.

Production was set up at

KraussMaffei of Munich from early 1964 onward, with deliveries of the first

batch between September 1965[6] and July 1966. The Leopard was soon being

purchased from Germany by a number of NATO members and other allies, including (in

chronological order) Belgium (1968), the Netherlands (1969), Norway (1970),

Italy (1971), Denmark (1976), Australia (1976), Canada (1978), Turkey (1980)

and Greece (1981). Germany has a strict export-policy for their military

equipment. Greece, Spain and Chile, while still under dictatorships, purchased

the French AMX-30 instead.

Description

The Leopard 1 has a conventional

layout shared with numerous other post-World War II tanks, with the driver's

compartment located in the front (on the right side, accessed from a hatch in

the hull roof which opens to the left) fighting compartment with a rotating

turret in the centre (the commander and gunner are seated in the right half of

the turret and access their positions from a single-piece hatch in turret roof,

on the right side), while the loader takes the left half (and is provided with

his own rear-opening hatch) and engine compartment in the rear of the hull,

separated from the crew compartment with a fireproof bulkhead.

The armament consists of a 105

mm L7A3 rifled main gun (production licensed from the UK Royal Ordnance

Factory) which was not stabilized on the first production series, and two MG 1

(later replaced with the MG3) machine guns: one is installed co-axial with the

main gun (1,250 rounds are carried for it), while a second, anti-aircraft

machine gun, is mounted on a skate rail above the gunner's hatch. For defensive

purposes, the tank has two banks of four (4) electrically fired smoke grenade

launchers on both sides of the turret, which can be fired individually or in a

salvo. A reload kit with eight further smoke grenades was carried inside the

turret.[7] The main gun uses NATO-standard 105 mm ammunition, with the majority

of the loadout (42 rounds) stored in an ammunition magazine inside of the hull,

to the left of the driver's station, 3 rounds are kept in a ready rack in front

of the hull magazine—for immediate use—and another 15 rounds are racked inside

the turret, for a total of 60 rounds carried onboard.

The gunner takes position in

front of and below the commander and is provided with a single, forward-facing

observation periscope and the main sights; these consist of a

Turmentfernungsmesser (TEM) 1A stereoscopic rangefinder (1,720 mm basis length

with a coincidence mode) which has a selectable ×8 or ×16 magnification and is

linked with the main gun, as well as a co-axial TZF 1A telescopic sight (×8

magnification) which has a moving graticule for several types of ammunition.

The twin, horizontally-opposed optical heads for the TEM 1A are located on both

sides of the turret in armoured housings and covered by protective flaps

operated by the gunner from inside the turret.[7] The commander maintains

all-around situational awareness via eight (8) periscopes, one of which can be

substituted for an active infrared (IR) night sight. He was provided with an

independent, swivel-mounted Turmrundblick-Pankrat (TRP) 1A variable

magnification periscope (×6 to ×20 magnification) installed in the turret roof,

in front of the commander's cupola, that could be slaved to the main gun and

allow the commander to override the gunner and slew the turret. The searchlight

for the active IR night vision system was designated XSW-30-U and was mounted

above the main gun on the mantlet, offset to the left. It could be removed and

stowed in the rear turret bustle when not in use. The searchlight had a range

of up to 1,200 m in ideal conditions, in the IR mode (covered by a special IR

filter cover), or up to 1,500 m when projecting just white light. In later

variants of the Leopard, a slightly modified, XSW-30-V searchlight was used.

Finally, the loader has two (2) periscopes to monitor a designated sector

around the vehicle.

The tank is powered by an MTU MB

838 Ca-M500 turbocharged diesel engine that develops approx. 610 kilowatts (820

hp) at 2,200 rpms. This is a liquid-cooled, 37.4 litre, ten-cylinder,

four-stroke engine in the V-90 configuration with multi-fuel capability but

which was typically run on diesel fuel (NATO designation F-54) consuming

approx. 190 litres per 100 km. The engine, along with its cooling system is

coupled into a "powerpack" with a 4HP-250 transmission system, built

by ZF which has a hydraulic torque converter, locking clutch, planetary gearbox

and pivot turn mechanism (for each of the gears). The entire powerpack with

transmission can be replaced in the field in approx. 20 minutes as it is mated

to the hull by means of quick disconnect couplings.

The tank suspension system has

14 independent torsion bars each with a control arm, and 10 hydraulic shock

absorbers which are installed on the 1st, 2nd, 3rd, 6th and 7th pairs of road

wheels. The running gear has seven (7) pairs of dual road wheels with

rubber-tyres, a rear-mounted drive sprocket, frontal idler wheel and four

return rollers on either side.

The Leopard's hull is fabricated

from welded armoured plate of varying thickness and geometry, while the turret

is a complex all-cast component. Crew protection was enhanced with an automatic

(manual trigger also available) fire suppression system and an NBC protection

system, which produces an overpressure in the crew compartment and provides

filtration of supplied air. The Leopard 1 can ford water obstacles (up to 1.20

m deep) by wading without any prior preparation; deeper obstacles (up to 2.25 m

depth) can be negotiated by sealing the tank and fitting a foldable snorkel

over the commander's cupola; two bilge pumps are provided to remove any water

accumulated.

Variants

Leopard 1A1

After the last vehicle from the

first four production series was delivered, the Bundeswehr initiated an upgrade

programme in 1970 to increase the combat effectiveness of its tanks. Known as

the Leopard A1 (later Leopard 1A1, after the introduction of the Leopard 2),

these tanks received a new gun stabilization system from Cadillac Gage (full

stabilization in both elevation and traverse, as well as powered elevation from

-9° to +20°) that allowed the tank to fire effectively on the move. The 1A1

added metal-rubber skirts along the hull flanks to protect against HEAT

warheads, and the gun barrel was wrapped in a jacket to reduce deviation from

thermal loads. The track was changed to a D640A double-pin type with

detachable, rectangular rubber pads instead of the earlier double-pin Diehl

D139E2 track with vulcanised treads. The rubber pads of the new tracks could be

easily replaced with metal X-shaped grousers for movement on ice and snow. 20

grousers were provided for each tank and stored on brackets on the front hull

upper glacis when not in use. A new snorkel was developed that allowed for

underwater driving to a depth of 4 m after sealing the tank with special plugs.

The driver's and commander's active infrared night vision periscopes were

replaced with passive image intensification night sights.

Between 1975 and 1977, all of

the tanks in the first four batches were brought to the Leopard 1A1A1 standard,

and given additional turret armour developed by Blohm & Voss which

consisted of rubber-lined steel plates bolted to the turret (including the rear

turret basket) with shock-resistant spacers. The gun mantlet received a

wedge-shaped armoured cover made from welded steel plates and the engine's air

intake system was improved. Thus upgraded vehicles weighed 42.4 tonnes.

An upgrade in the 1980s added a

hybrid LLLTV/passive IR aiming and observation system, which were being handed

down from the Leopard 2 as they were themselves upgraded to thermal imagers.

The PZB 200 low light level television (LLLTV) system with IRS 100 infrared

scanner was developed by AEG-Telefunken and mounted in a protective cage on the

mantlet, above the main gun, creating the Leopard 1A1A2. The system combined an

LLTV camera which was a type of image intensification device producing a TV

picture on the commander's and gunner's monitors, coupled with an IR scanner

(sensitive to thermal differences in the 3-5 μm wavelengths and based on a PbSe

detector) which would superimpose the processed IR image over the LLLTV signal

to improve target detection and identification.

In the late 1980s, all-digital

SEM 80/90 VHF radios were issued to the Bundeswehr and installed in various

models of the Leopard 1; the Leopard 1A1A1 with these new radios received the

Leopard 1A1A3 designator, and those vehicles with the LLLTV/IR system and SEM

80/90 radios would be known as the Leopard 1A1A4.

Leopard 1A2

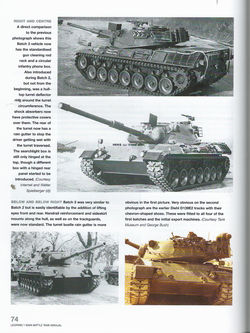

Cast turret Leopard 1A2A1 with

upgraded LLLTV/IR night sights mounted inside of a protective cage to the right

of the IR searchlight on the gun mantlet.

The first 232 tanks of the fifth

production batch were delivered as the Leopard 1A2 between 1972 and 1974. The

A2 included a heavier and better armoured cast turret which was visually

difficult to distinguish from the previous type. The most notable difference

were the oval, as opposed to round, armoured housings for the optics of the TEM

rangefinding sight. The Leopard 1A2 tanks were not subject to further armour

upgrades as was the 1A1, but did receive improvements to the NBC protection

system.

Throughout their service, these

tanks would receive several other upgrades: the Leopard 1A2A1 received

AEG-Telefunken LLLTV/IR sights, the Leopard 1A2A2 received digital radios, and

the Leopard 1A2A3 got both.

Leopard 1A3

The Leopard 1A3 received a new,

welded turret which can be distinguished by its angular shape. Seen here is a

vehicle of PzGrenBtl 301 in 1984.

The next 110 vehicles in the

fifth production batch were fitted with a new type of welded turret designed by

Blohm & Voss, which was equipped with spaced armour (consisting of two

steel plates with a plastic filling between them), and a wedge-shaped gun

mantlet, resulting in the Leopard 1A3. Although the level of armour protection

was equivalent to the cast turrets of the prior A2, the internal volume was

increased by 1.5 m³ and the effective protection level was increased. The

commander was given an improved TRP 2A independent observation periscope and

both of the loader's fixed periscopes were replaced with a single unit with

tilt and traverse adjustment. Most of the vehicles of this batch were allocated

to the 10th and 12th Panzer Divisions. Henceforth, all newly manufactured

Leopard 1 tanks from Krauss-Maffei and MaK would use this welded turret, as

casting large parts such as tank turrets was overly complex and the welded

design carried greater upgrade potential.

Subsequent upgrades were

parallel to the 1A2 models: the Leopard 1A3A1 with improved night sights,

Leopard 1A3A2 with the new radios, and the Leopard 1A3A3 with both.

Leopard 1A4

Leopard 1A4 at the German Panzer

Museum Munster. The vehicle is displayed with a deep fording snorkel, which

would be used to draw in combustion air for the operation of the engine while

submerged in water.

West German Leopard 1A4 (far

right) at the Canadian Army Trophy gunnery competition in 1979.

The Leopard 1A4 formed the sixth

batch of 250 vehicles (215 manufactured by Krauss-Maffei and 35 from MaK),

starting delivery in 1974. The 1A4 was externally similar to the 1A3, but

included a new, integrated fire control system. This consisted of a stabilized

PERI R12 independent sight for the commander, a new EMES 12A1 stereoscopic

rangefinder coupled to the gunner's primary sight, a fully stabilized main gun

and FLER HG ballistic computer. Many of these systems were derived from the

Leopard 2 program. While the EMES 12A1 was still just an optical rangefinder

(the desired laser rangefinder was still in development), it was used for

target acquisition and linked to the ballistic computer, which would

automatically produce a lead angle once the range was measured and several

other ballistic inputs were computed. This solution reduced the time between

target acquisition and engagement and increased the first-round-hit

probability. The PERI R12 sight improved the commander's efficiency, allowing

him to acquire and relay targets to the gunner considerably faster in what can

be considered the precursor to "hunter-killer" capability. The PERI

R12 sight also had an integrated night channel (2nd generation image

intensifier) toggled with a switch; a considerable improvement over the prior

TRP sights which had no night vision capabilities and had to be un-installed

and exchanged for an infrared device. The PERI R12 was mounted in the turret

roof forward of the commander's cupola and was protected by wire guards. The gunner's

forward-looking observation periscope was deleted. The new equipment for the

fire control system consumed additional space and the ammunition load was

reduced to 55 rounds, of which 42 were stored in the hull-mounted magazine,

while the remaining 13 rounds were in ready racks in the turret. The hull

received only minor modifications involving the layout of the tow cables and

storage rails for the winter grousers. Final deliveries of the Leopard 1A4 for

the Bundeswehr took place in 1976 and would mark the conclusion of Leopard 1

production for Germany.

Leopard 1A5

In 1980, a research program was

undertaken to investigate further improvements to the Leopard 1, stipulating

the need for a new fire control system/ballistic computer and thermal camera

for effective night and all-weather capabilities to effectively fight against

the more sophisticated Soviet T-64B, T-72B and T-80B series of tanks. A crucial

part of the upgrade was the introduction of more effective ammunition,

including new APFSDS rounds. The decision was made to base the upgrade on

earlier models which were no longer competitive. The resulting Leopard 1A5 was

a retrofit of 1,225 Leopard 1A1A1 vehicles from Bundeswehr stocks.

After trials, the Krupp-Atlas

Elektronik EMES 18 fire control system, which was developed from the EMES 15

used on the Leopard 2, was selected in December 1983. The large, box-like

armoured enclosure for the EMES 18 primary sight was mounted on top of the

turret, in front of the commander's hatch, and contained a fully stabilized

(both in azimuth and elevation) head mirror which was used for the daylight

vision channel (×12 magnification and 5° field of view), Nd:YAG laser

rangefinder and a WBG-X thermal imager from Carl Zeiss. The gunner would access

both day and night channels from the primary sight via binocular eyepiece, in

addition to his back-up telescopic daytime sight (the TZF 1A from previous

models). The commander would receive imagery from the gunner's primary sight on

his ocular by way of a light pipe. His station retained the panoramic periscope

(improved model TRP 5A) and vision blocks, with the TRP sight and forward

facing vision block raised to clear the EMES 18 sight housing. Both commander and

gunner could control the turret traverse with hand controllers, but an override

function was given to the commander. In a typical engagement scenario, the

commander would identify the target and slew the turret to its azimuth, then

hand the target over to the gunner. Using the primary sight, the gunner would

aim at the target and lase it to obtain a range; tracking would be initiated

(if the target was moving). The fire control computer would then take the

manual (ammunition type, target speed – obtained from the horizontal turret

traverse rate) and automatic inputs (vehicle cant correction from a vertical

sensor, atmospheric conditions, powder temperature, altitude) and continuously

compute superelevation and lead solutions for the main armament. Control

signals were transmitted to the turret and main gun drives to align the plotted

aiming mark with the main gun bore axis, without disturbing the line of sight.

Once these were coincident, the gunner could fire. The fire control computer

contained ballistic information for up to 7 different ammunition types.

Upgraded tanks initially made use of the existing Cadillac-Gage stabilization

system, but since 1988, all Leopard 1A5s were either built or retrofitted with

a new SRK servo-hydraulic turret and gun control system. The bulbous,

horizontally-opposed objective housings for the optical rangefinder were

removed and their openings in the turret—sealed with armour plates. Two new

types of high performance kinetic energy APFSDS rounds were introduced for use in

the Leopard 1A5: the DM23 (a variant of the Israeli M111 Hetz-6) and DM33

(Israeli M413 Hetz-7) rounds. One test vehicle was armed with the smoothbore

120 mm main gun and all A5s are adapted to carry this weapon, but the concept

did not proceed into production. The running gear on these vehicles was

improved with strengthened torsion bars and shock absorber mounts. Lifting

hooks were welded to the hulls of early production vehicles which lacked them

(first and second batches) and the driver's station received high pressure

washers for his observation periscopes (later installed in most Leopard 1s in

German service). A three-tone camouflage was also applied to all tanks

undergoing the conversion to A5 standard.

The first modified vehicle was

delivered in December 1986 and the conversion process ran until 2001/2002 which

coincided with a reduction of armoured forces in the Bundeswehr, resulting in

fewer Leopard 1A5 tanks delivered than were originally authorized. Most of the

Leopard 1A5 tanks delivered to the Bundeswehr were assigned to formations of

the former East Germany Army. Leopard 1A5s which received new SEM 80/90 VHF

radios in the late 1980s were designated Leopard 1A5A1.

Since then, almost all users of

the Leopard 1 have applied similar changes to their own vehicles, and in most

ways the 1A5 can be considered the "standard" Leopard 1 today.

Leopard 1A6

The Leopard 1A6 prototype was a

single Leopard 1 A1A1 testbed, modified with additional armour on the turret

and equipped with a 120 mm L/44 gun. The project was ended in 1987, as the

Leopard 2 was in widespread service at this point and the 1A5 offered a more

reasonable upgrade path for a fraction of the cost.

Modified and derivative vehicles

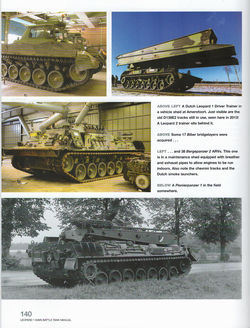

An armoured engineering vehicle

"Dachs" (Badger) German Army

Bergepanzer 2 of the Royal

Netherlands Army with erected crane

A bridgelayer "Biber"

(Beaver) with armoured vehicle-launched bridge

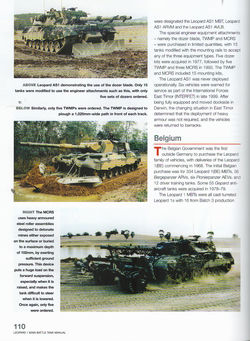

Simultaneous to the production

of the battle tanks, a number of engineering, bridging and recovery vehicles

were developed, as well as a number of versions used in the anti-aircraft role.

The most well known Leopard

variants are the Bridgelayer "Biber" (Beaver), "Bergepanzer

2" armoured recovery vehicle, "Pionierpanzer 2 Dachs" (Badger)

armoured engineer vehicle and the "Gepard" self-propelled anti-aircraft

gun. The Warsaw Pact equivalent of the Gepard is the ZSU-23-4. Marconi

Electronic Systems once offered conversions to the Marksman SPAAG for existing

users of the Leopard 1. The Leopard 1 chassis would be used to carry the

Marksman turret.

The Canadian Army operates the

Beaver Armoured vehicle-launched bridge, Taurus ARV, and Badger AEV, all based

on the Leopard 1.

The United Kingdom's Royal

Marines operate a vehicle known as the Hippo beach armoured recovery vehicle.

The Hippo is a conversion of a Leopard 1A5 chassis by Alvis Moelv. The main

alteration has been the replacement of the turret with a raised superstructure

that resembles the wheelhouse of a boat. The original 830 hp (634 kW) diesel

engine has been retained, but the gearing of the transmission had been lowered,

reducing the vehicle's road speed to 32 km/h (20 mph), but increasing tractive

effort to 250 kN (56,000 lbf). Other modifications include the addition of

working platforms, a nosing block, raised air intakes and an Auxiliary power

unit. This raised the weight of the vehicle from 42.5 tonnes to 50 tonnes. The

Hippo has a fording depth of 2.95 m (10 ft) and can pull vehicles up to 50

tonnes weight or push off from the beach a 240 tonne displacement landing

craft.

German company Flensburger

Fahrzeugbau is the producer of a vehicle known as Wisent 1, a modernization of

the Bergepanzer 2, it comes in Armoured Recovery Vehicle, Armoured Engineer

Vehicle and Mine Clearing vehicle versions. The Wisent 1 is known to be operated

by Denmark and Ukraine.