-------------------------------------------------------------------------------------------------------------------

Additional Information from Internet Encyclopedia

The Panther was a German medium tank deployed

during World War II on the Eastern and Western Fronts in Europe from mid-1943

to its end in 1945. It had the ordnance inventory designation of Sd.Kfz. 171.

Until 27 February 1944, it was designated as the Panzerkampfwagen V Panther

when Hitler ordered that the Roman numeral "V" be deleted. Contemporary

English language reports sometimes refer to it as the Mark V.

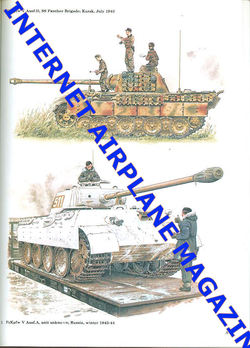

The Panther was intended to counter the Soviet

T-34 and to replace the Panzer III and Panzer IV. Nevertheless, it served

alongside the Panzer IV and the heavier Tiger I until the end of the war. It is

considered one of the best tanks of World War II for its excellent firepower

and protection, although its reliability was less impressive.

The Panther was a compromise. While having

essentially the same engine as the Tiger I, it had more efficient frontal hull

armour, better gun penetration, was lighter and faster, and could traverse

rough terrain better than the Tiger I. The trade-off was weaker side armour,

which made it vulnerable to flanking fire. The Panther proved to be effective

in open country and long range engagements, but did not provide enough high

explosive firepower against infantry.

The Panther was far cheaper to produce than the

Tiger I, and only slightly more expensive than the Panzer IV. Key elements of

the Panther design, such as its armour, transmission, and final drive, were

simplifications made to improve production rates and address raw material

shortages. The overall design remained somewhat over-engineered. The Panther

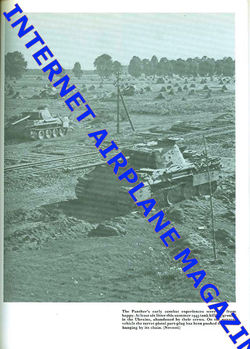

was rushed into combat at the Battle of Kursk despite numerous unresolved

technical problems, leading to high losses due to mechanical failure. Most

design flaws were rectified in the German retreat, though the bombing of

production plants, increasing shortages of high quality alloys for critical

components, shortage of fuel and training space, and the declining quality of

crews all impacted the tanks's effectiveness.

The weight of the production model was increased

to 45 tonnes from the original plans for a 35 tonne tank. Hitler was briefed

thoroughly on the comparison between the MAN and DB designs in the report by

Guderian's tank commission. Armour protection appeared to be inadequate, while

"the motor mounted on the rear appeared to him correct". He agreed

that the "decisive factor was the possibility of quickly getting the tank

into production". On 15 May 1942, Oberst Fichtner informed MAN that Hitler

had decided in favour of the MAN Panther and ordered series production. The

upper glacis plate was to be increased from 60 mm (2.4 in) to 80 mm (3.1 in).

Hitler demanded that an increase to 100 mm (3.9 in) should be attempted and

that at least all vertical surfaces were to be 100 mm (3.9 in); the turret

front plate was increased from 80 mm (3.1 in) to 100 mm (3.9 in).

The Panther was rushed into combat before all of

its teething problems had been corrected. Reliability was considerably improved

over time, and the Panther proved to be a very effective fighting vehicle, but

some design flaws, such as its weak final drive units, were never corrected.

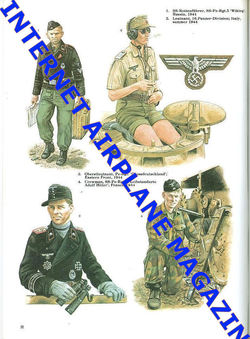

The crew had five members: driver, radio operator

(who also fired the bow machine gun), gunner, loader, and commander.

The first 250 Panthers were powered by a Maybach

HL 210 P30 engine, V-12 petrol engine, which delivered 650 metric hp at 3,000

rpm and had three simple air filters. Starting in May 1943, the Panthers were

built using the 700 metric hp (690 hp, 515 kW) at 3,000 rpm, 23.1 litre Maybach

HL 230 P30 V-12 petrol engine. To save aluminium, the light alloy block used in

the HL 210 was replaced by a cast iron block. Two multistage

"cyclone" air filters were used to improve dust removal. Due to the

use of low grade petrol, the engine power output was reduced. With a capacity

of 730 litres (160 imperial gallons; 190 US gallons) of fuel, a fully fuelled

Panther's range was 200 km (120 mi) on surfaced roads and 100 km (62 mi) cross

country.

The HL 230 P30 engine was a very compact tunnel

crankcase design, which kept the space between the cylinder walls to a minimum.

The crankshaft was composed of seven discs, each with an outer race of roller

bearings, and a crankshaft pin between each disc. To reduce the length of the

engine further, by one-half a cylinder diameter, the two banks of 6 cylinders

of the V-12 were not offset – the "big ends" of the connecting rods

of each cylinder pair in the "V" where they mated with the crankpin

were thus at the same spot with respect to the engine block's length rather

than offset; this required a "fork and blade" matched pair of conrods

for each transversely oriented pair of cylinders. Usually, "V"-form

engines have their transversely paired cylinders' conrods' "big ends"

simply placed side by side on the crankpin, with their transverse pairs of

cylinders offset to match. This compact arrangement with the connecting rods

was the source of considerable problems initially. Blown head gaskets were

another problem, which was corrected with improved seals in September 1943.

Improved bearings were introduced in November 1943. An engine governor was also

added in November 1943 that reduced the maximum engine speed to 2500 rpm. An

eighth crankshaft bearing was added beginning in January 1944 to reduce motor

failures.

The engine compartment space was designed to be

watertight so that the Panther could ford water obstacles; however, this made

the engine compartment underventilated and prone to overheating. The fuel

connectors in the early models were not insulated, leading to the leakage of

fuel fumes into the engine compartment, which caused engine fires in the early

Panthers. Additional ventilation was added to draw off these gases, which only

partly solved the problem of engine fires. Other measures taken to reduce this

problem included improving the coolant circulation inside the motor and adding

a reinforced membrane spring to the fuel pump. Despite the risks of fire, the

fighting compartment was relatively safe due to a solid firewall that separated

it from the engine compartment.

Engine reliability improved over time. A French

assessment in 1947 of their stock of captured Normandy Panther A tanks

concluded that the engine had an average life of 1,000 km (620 mi) and maximum

life of 1,500 km (930 mi).

The suspension consisted of front drive sprockets,

rear idlers and eight double-interleaved rubber-rimmed steel road wheels on

each side — in the so-called Schachtellaufwerk design, suspended on a dual

torsion bar suspension. The dual torsion bar system, designed by Professor

Ernst Lehr, allowed for a wide travel stroke and rapid oscillations with high

reliability, thus allowing for relatively high speed travel over undulating

terrain. The extra space required for the bars running across the length of the

bottom of the hull, below the turret basket, increased the overall height of

the tank and also prevented the provision for an escape hatch in the hull

bottom[dubious – discuss]. When damaged by mines, the torsion bars often

required a welding torch for removal.

The Panther's suspension was overengineered and

the Schachtellaufwerk interleaved road wheel system made replacing inner road

wheels time consuming (though it could operate with missing or broken wheels).

The interleaved wheels also had a tendency to become clogged with mud, rocks

and ice, and could freeze solid overnight in the harsh winter weather that

followed the autumn rasputitsa mud season on the Eastern Front. Shell damage

could cause the road wheels to jam together and become difficult to separate.

Interleaved wheels had long been standard on all German half-tracks. The extra

wheels did provide better flotation and stability, and also provided more

armour protection for the thin hull sides than smaller wheels or

non-interleaved wheel systems, but the complexity meant that no other country

ever adopted this design for their tanks. In September 1944, and again in

March/April 1945, M.A.N. built a limited number of Panthers with overlapping,

non-interleaved steel-rimmed 80 cm diameter roadwheels originally designed for

Henschel's Tiger II and late series Tiger I Ausf. E tanks. These steel-rimmed

roadwheels were introduced from chassis number 121052 due to raw material

shortages.

From November 1944 through February 1945, a

conversion process began to use sleeve bearings in the Panther tank, as there

was a shortage of ball bearings. The sleeve bearings were primarily used in the

running gear; plans were also made to convert the transmission to sleeve

bearings, but were not carried out due to the ending of Panther production.

Steering was accomplished through a seven-speed AK

7-200 synchromesh gearbox, designed by Zahnradfabrik Friedrichshafen (ZF), and

a MAN single radius steering system, operated by steering levers. Each gear had

a fixed radius of turning, ranging from 5 m (16 ft) for 1st gear up to 80 m

(260 ft) for 7th gear. The driver was expected to judge the sharpness of a turn

ahead of time and shift into the appropriate gear to turn the tank. The driver

could also engage the brakes on one side to force a sharper turn. This manual

steering was a much simplified design, compared to the sophisticated

dual-radius hydraulically controlled steering system of the Tiger tanks.

The AK 7-200 transmission was also capable of

pivot turns, but this high-torque method of turning could cause failures of the

final drive.

The Panthers' main weakness was its final drive

unit. The problems stemmed from several factors. The original MAN proposal had

called for the Panther to have an epicyclic gearing (planetary) system in the

final drive, similar to that used in the Tiger I. Germany suffered from a

shortage of gear-cutting machine tools and, unlike the Tiger tanks, the Panther

was intended to be mass-produced. To achieve the goal of higher production

rates, numerous simplifications were made to the design and its manufacture.

This process was aggressively pushed forward, sometimes against the wishes of

designers and army officers, by the Chief Director of Armament and War

Production, Karl-Otto Saur (who worked under, and later succeeded,

Reichminister Speer). Consequently, the final drive was changed to a double

spur system. Although much simpler to produce, the double spur gears had

inherently higher internal impact and stress loads, making them prone to

failure under the high torque requirements of the heavy Panther tank. Because

of the significant numbers of breakdowns, the Wehrmacht was forced to move the

Panther D and Tiger I tanks by rail, throughout 1943. The tanks could not

participate in major movements of more than 100 km without adversely affecting

unit strengths due to breakdowns.

Initial production Panthers had a face-hardened

glacis plate (the main front hull armour piece), but as armour-piercing capped

rounds became the standard in all armies (thus defeating the benefits of

face-hardening, which caused uncapped rounds to shatter), this requirement was

deleted in March 1943. By August 1943, Panthers were being built only with a

homogeneous steel glacis plate.[50] The front hull had 80 mm (3.1 in) of armour

angled at 55 degrees from the vertical, welded but also interlocked for

strength. The combination of well-sloped and thick armour meant that heavy Allied

weapons, such as the Soviet 122 mm A-19, 100 mm BS-3 and US 90 mm M3 were

needed to assure penetration of the upper glacis at all combat ranges.

The armour for the side hull and superstructure

(the side sponsons) was much thinner (40–50 mm (1.6–2.0 in)). The thinner side

armour was necessary to keep the tanks' weight down, but it made the Panther

vulnerable to hits from the side by all Allied tank and anti-tank guns. German

tactical doctrine for the use of the Panther emphasized the importance of flank

protection. 5 mm (0.20 in) thick spaced armour, known as Schürzen, intended to

provide protection for the lower side hull from Soviet anti-tank rifle fire,

was fitted on the hull side. Zimmerit coating against magnetic mines started to

be applied at the factory on late Ausf D models beginning in September 1943; an

order for field units to apply Zimmerit to older versions of the Panther was

issued in November 1943. In September 1944, orders to stop all application of

Zimmerit were issued, based on false rumours that hits on the Zimmerit had

caused vehicle fires.

Panther crews were aware of the weak side armour

and made augmentations by hanging track links or spare roadwheels onto the

turret and/or the hull sides. The rear hull top armour was only 16 mm (0.63 in)

thick, and had two radiator fans and four air intake louvres over the engine

compartment that were vulnerable to strafing by aircraft.

As the war progressed, Germany was forced to

reduce or no longer use certain critical alloys in the production of armour

plate, such as those including nickel, tungsten and molybdenum; this resulted

in lower impact resistance levels compared to earlier armour. Allied bombers

struck the Knaben mine in Norway and stopped a key source of molybdenum;

supplies from Finland and Japan were also cut off. The loss of molybdenum, and

its replacement with other substitutes to maintain hardness, as well as a

general loss of quality control, resulted in an increased brittleness in German

armour plate, which developed a tendency to fracture when struck with a shell.

Testing by U.S. Army officers in August 1944 in Isigny, France showed

catastrophic cracking of the armour plate on two out of three Panthers

examined.

The main gun was a Rheinmetall-Borsig 7.5 cm KwK

42 (L/70) with semi-automatic shell ejection and a supply of 79 rounds (82 on

Ausf. G). The main gun used three different types of ammunition: APCBC-HE

(Pzgr. 39/42), HE (Sprgr. 42) and APCR (Pzgr. 40/42), the last of which was

usually in short supply. While it was of a calibre common on Allied tanks, the

Panther's gun was one of the most powerful of World War II, due to the large

propellant charge and the long barrel, which gave it a very high muzzle

velocity and excellent armour-piercing qualities — among Allied tank guns of

similar calibre, only the British Sherman Firefly conversion's Ordnance QF

17-pounder gun, of 3 inch (76.2mm) calibre, and a 55 calibre long (L/55)

barrel, had more potential hitting power. The flat trajectory also made hitting

targets much easier, since accuracy was less sensitive to errors in range

estimation and increased the chance of hitting a moving target, though these

same attributes made the gun a poor infantry-support weapon using HE ammo. The

Panther's 75 mm gun had more penetrating power than the main gun of the Tiger I

heavy tank, the 8.8 cm KwK 36 L/56, although the larger 88 mm projectile might

inflict more damage if it did penetrate.

The tank typically had two MG 34 armoured fighting

vehicle variant machine guns featuring an armoured barrel sleeve. An MG 34

machine gun was located co-axially with the main gun on the gun mantlet; an

identical MG 34 was located on the glacis plate and fired by the radio

operator. Initial Ausf. D and early Ausf. A models used a "letterbox"

flap enclosing its underlying thin, vertical arrowslit-like aperture, through

which the machine gun was fired. In later Ausf A and all Ausf G models

(starting in late November-early December 1943), a ball mount in the glacis

plate with a K.Z.F.2 machine gun sight was installed for the hull machine gun.

The front of the turret was a curved 100 mm (3.9

in) thick cast armour mantlet. Its transverse-cylindrical shape meant that it

was more likely to deflect shells, but the lower section created a shot trap.

If a non-penetrating hit bounced downwards off its lower section, it could

penetrate the thin forward hull roof armour, and plunge down into the front

hull compartment. Penetrations of this nature could have catastrophic results,

since the compartment housed the driver and radio operator sitting along both

sides of the massive gearbox and steering unit. Also, four magazines containing

main gun ammunition were located between the driver/radio operator seats and

the turret, directly underneath the gun mantlet when the turret was facing forward.

From September 1944, a slightly redesigned mantlet

with a flattened and much thicker lower "chin" design started to be

fitted to Panther Ausf G models, the chin being intended to prevent such

deflections. Conversion to the "chin" design was gradual, and

Panthers continued to be produced to the end of the war with the rounded gun

mantlet.

The Ausf A model introduced a new cast armour

commander's cupola, replacing the forged cupola. It featured a steel hoop to

which a third MG 34 or either the coaxial or the bow machine gun could be

mounted for use in the anti-aircraft role.

The first Panthers (Ausf D) had a hydraulic motor

that could traverse the turret at a maximum rate of one complete revolution in

one minute, independent of engine speed. This was improved in the Ausf A model

with a hydraulic traverse that varied with engine speed; one full turn taking

46 seconds at an engine speed of 1,000 rpm but only 15 seconds if the engine

was running at 3,000 rpm.[70] This arrangement was a weakness, as traversing

the Panther's turret rapidly onto a target required close coordination between

the gunner and driver, who had to run the engine to maximum speed. By

comparison, the M4 Sherman's electrically traversed turret rotated at up to 360

degrees in 15 seconds and was independent of engine speed, which gave it an

advantage over the Panther in close-quarters combat. A hand traverse wheel was

provided for the Panther gunner to make fine adjustment of his aim.

Ammunition storage for the main gun was a weak

point. All the ammunition for the main armament was stored in the hull, with a

significant amount stored in the sponsons. In the Ausf D and A models, 18 rounds

were stored next to the turret on each side, for a total of 36 rounds. In the

Ausf G, which had deeper sponsons, 24 rounds were stored on each side of the

turret, for a total of 48 rounds. In all models, four rounds were also stored

in the left sponson between the driver and the turret. An additional 36 rounds

were stored inside the hull of the Ausf D and A models – 27 in the forward hull

compartment directly underneath the mantlet. In the Ausf G, the hull ammunition

storage was reduced to 27 rounds total, with 18 rounds in the forward hull

compartment. For all models, three rounds were kept under the turntable of the

turret. The stowage of 52 rounds of ammunition in the side sponsons made this

area the most vulnerable point on the Panther since penetration here usually

led to catastrophic ammunition fires.

The loader was stationed in the right side of the

turret. With the turret facing forward, he had access only to the right sponson

and hull ammunition, and so these served as the main ready-ammunition bins.