8110 brushless motor outer rotor power generation stator core 81x10mm 36N40P

Product name: 10010 outer rotor motor stator core

Product material: imported silicon steel plate

Slot structure: 36N34P, 36N38P, 36N40P, 36N42P, 36N48P, etc.

Size specifications: diameter 100mm * inner diameter 78mm * thickness 10mm

Surface treatment: insulating coating + anti-corrosion and anti-rust coating

Product net weight: 105g

Applicable scenarios: ultra-high thrust aircraft, aerial photography drones, hollow shaft pan/tilt motors, robot joint torque motors, direct drive torque motors, high-power brushless DC motors, disc generators, etc.

Product material: imported silicon steel plate

Slot structure: 36N34P, 36N38P, 36N40P, 36N42P, 36N48P, etc.

Size specifications: diameter 100mm * inner diameter 78mm * thickness 10mm

Surface treatment: insulating coating + anti-corrosion and anti-rust coating

Product net weight: 105g

Applicable scenarios: ultra-high thrust aircraft, aerial photography drones, hollow shaft pan/tilt motors, robot joint torque motors, direct drive torque motors, high-power brushless DC motors, disc generators, etc.

The product is made of imported high-performance silicon steel sheets and laminated through high-speed CNC punching. It has the advantages of low eddy current loss and high saturation magnetic flux density. It has a multi-slot multi-pole structure and fractional slot windings. The motor produced is light in weight and low in power density. Large size, high conversion efficiency, small cogging effect, large torque, the surface of the product is painted, waterproof, rust-proof, and corrosion-resistant. When operating in harsh and humid environments, it can greatly extend the service life of the motor. It can be used to manufacture anti-gravity systems for high-thrust and high-load aircraft, equipped with high-performance electromagnetic steel + carbon fiber propellers (28~30 inches), and the maximum pulling force can reach 14KG (such as DJI E5000 multi-rotor power system M10 (10010) motor).

This product is the core component of the motor. Except for the above product description, no other information will be provided. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

Product name: 10010 motor outer rotor yoke steel sleeve

Product material: low carbon steel

Suitable stator: outer diameter 100mm * height 10mm

Suitable magnet: length 10mm * width 6mm * thickness 3mm

Adaptation structure: 36N40P, 36N42P, etc.

Size specifications: inner diameter 107.2mm * outer diameter 110.6mm * height 13mm

Surface technology: prevent blackening and rust

Product net weight: 60g

Product material: low carbon steel

Suitable stator: outer diameter 100mm * height 10mm

Suitable magnet: length 10mm * width 6mm * thickness 3mm

Adaptation structure: 36N40P, 36N42P, etc.

Size specifications: inner diameter 107.2mm * outer diameter 110.6mm * height 13mm

Surface technology: prevent blackening and rust

Product net weight: 60g

This product is customized for 10010 disc stator core. It is one of the three core components of the motor yoke (all with a shell). It is recommended to purchase high-performance electromagnetic steel from this site for support purposes. The steel can be used in combination with 36N40P or 36N42P.

Since it is difficult to rotate such thin-walled pipe fittings, there are turning tool lines on the inner and outer walls. In order to avoid dimensional deformation caused by repeated clamping of the workpiece, no further fine grinding and polishing will be carried out, and the use will not be affected. If you mind the appearance, please don't buy it.

This product is the core component of the motor. Except for the above product description, no other information will be provided. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

Product name: T-shaped flange hollow shaft (with circlip)

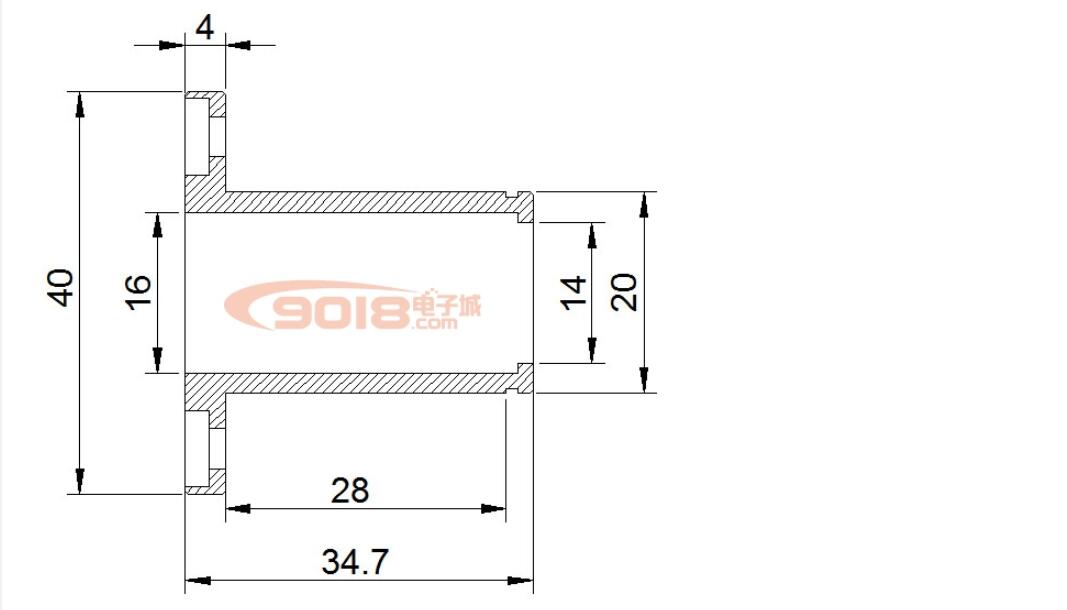

Size specifications: diameter 20mm * inner diameter 16mm * length 35mm, flange F40 * 4mm

Diameter tolerance: -0.02mm

Application scenarios: hollow motor shafts, rigid couplings, etc.

Size specifications: diameter 20mm * inner diameter 16mm * length 35mm, flange F40 * 4mm

Diameter tolerance: -0.02mm

Application scenarios: hollow motor shafts, rigid couplings, etc.

Dimension parameters (unit mm, diameter 20mm tolerance -0.02, other parameters may have a tolerance of 0.1mm):

This product is specially designed for large-diameter disc motors customized for stators 8110 and 10010. It is made of stainless steel rods, is waterproof, corrosion-resistant, and does not rust. The diameter tolerance is -0.02mm, and it is suitable for various inner diameters. 20mm deep groove ball bearings, angular contact bearings. The bookT shaft flange has 4 individual M4 thread holes evenly distributed on the end face, which can be used to fix various loads. The other four 4mm diameter through holes with counterbore holes are suitable for ISO7380 standard hexagon socket screws. The end of the shaft is provided with a spring groove of an elastic retaining ring, which can meet the needs of rapid assembly and positioning under low axial load. When the elastic ring cannot meet the axial load or reliability requirements, the elastic force of the spring is not high (for example, the axial tension of the 10010 disc motor can reach 14KG level. Such a large dynamic axial load may cause the fixed ring to loosen and the rotor to fly out. ), the end of the inner hole of the shaft is designed with a narrow side, and the 2 stopper can be used to fix the lock with 2 to 3 screws from the inner side of the hole to the outer end of the hole, which greatly improves the reliability. Elastic ring + limiter double protection to prevent the shaft from loosening.

Due to rotation, bearing inner diameter tolerance and other reasons, the shaft may not be easily inserted into the bearing inner ring. Please use fine sandpaper to polish the surface to ensure a better clearance fit or interference fit with the bearing. This product is made of stainless steel. Therefore, the surface has not been treated by any electroplating or other special coatings. Due to the repeated clamping of the workpiece during the processing, the transmission of friction, collision and other reasons, slight scratches on the surface will be caused. If the appearance is not Well, you can polish it yourself. Manual sanding operation guide under amateur conditions: install the shaft on an electric drill (or with its own motor), rotate at low speed for 300-1000, then wrap half of the sandpaper on the outer surface of the shaft, move forward and backward along the shaft and lightly sand it. To achieve the desired polishing effect. obtain. Pay attention to safety during the operation, wear thick cotton gloves, try to insert the bearing each time you polish, too much polishing, poor matching effect, affecting the balance of the motor rotor, too little polishing, difficult assembly, it is ideal to master the amount of grinding effect.

This product is the core component of the motor. Except for the above product description, no other information will be provided. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

Product name: High-strength electromagnetic steel for square Nd-Fe-B motor

Performance: N42H, dedicated to motor

Magnetization direction: radial thickness direction

Size: 10.5 * 5 * 3 mm

Tolerance: ± 0.05mm

Surface technology: electroplating anti-rust

Performance: N42H, dedicated to motor

Magnetization direction: radial thickness direction

Size: 10.5 * 5 * 3 mm

Tolerance: ± 0.05mm

Surface technology: electroplating anti-rust

The surface magnetic field strength of electromagnetic steel is much higher than that of ordinary black ferromagnetic steel, and it is more common than N35strong in Taobao market. It has high anti-demagnetization performance and can be used to manufacture various high-performance permanent magnet motors.

This product is the core component of the motor. Except for the above product description, no other information will be provided. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

Slot structure analysis and suggestions:

36N34P: The number of electromagnetic steel is less than the number of slots, the gap of electromagnetic steel is large, the processing accuracy of shell and electromagnetic steel is general, and the structure is firm, the cost is low, but the power density is low, the magnetic leakage is large, the torque is small, and the speed is fast. Suitable for airplanes with low vibration.

36N38P / 40P: The number of electromagnetic steel is greater than the number of slots, the gap of the electromagnetic steel is moderate, the machining accuracy of the shell and the electromagnetic steel is high, the cost is low, the power density is moderate, the vibration is small, and the torque pulsation volume is small, which is higher than that of 34P Torque, low speed, suitable for airplanes.

36N42P: The number of electromagnetic steel is greater than the number of slots, the gap of electromagnetic steel is small, the processing precision of the shell and electromagnetic steel is high, the cost is high, the power density is higher than the first three combinations, high torque, low speed, used in aircraft.

36N48P: There are far more electromagnetic steels than slots, the gap between the magnets is very small, the machining accuracy of the shell and the electromagnetic steel is very high, the cost is high, the torque pulsation is large at low speeds, and the power density is the highest All unit levels are combined, the best torque, the lowest speed, and the magnetic resistance is very strong. Usually suitable for high power and high torque, not sensitive to vibration. Theoretically, this is the upper limit of the pole combination and should not exceed 48P.

36N38P / 40P: The number of electromagnetic steel is greater than the number of slots, the gap of the electromagnetic steel is moderate, the machining accuracy of the shell and the electromagnetic steel is high, the cost is low, the power density is moderate, the vibration is small, and the torque pulsation volume is small, which is higher than that of 34P Torque, low speed, suitable for airplanes.

36N42P: The number of electromagnetic steel is greater than the number of slots, the gap of electromagnetic steel is small, the processing precision of the shell and electromagnetic steel is high, the cost is high, the power density is higher than the first three combinations, high torque, low speed, used in aircraft.

36N48P: There are far more electromagnetic steels than slots, the gap between the magnets is very small, the machining accuracy of the shell and the electromagnetic steel is very high, the cost is high, the torque pulsation is large at low speeds, and the power density is the highest All unit levels are combined, the best torque, the lowest speed, and the magnetic resistance is very strong. Usually suitable for high power and high torque, not sensitive to vibration. Theoretically, this is the upper limit of the pole combination and should not exceed 48P.

1.warranty period 60 dayS

Note:

We will post positive feedbacks to our customers after they are satisfied with our service and/or products, in case you are not satisfied with our products or service, please contact us about the issue that you encountered, we will try our best to resolve it for you. Our object is to satisfy all our customers. Please remember any issues can be resolved prior any open case or negative feedback comments.

We are a professional supplier of industrial control parts. We have a lot of products and only show a small number of products on the website.

If you need other products,please contact us. Thank you for coming to our store.